What is metal etching?

Jun 06, 2025

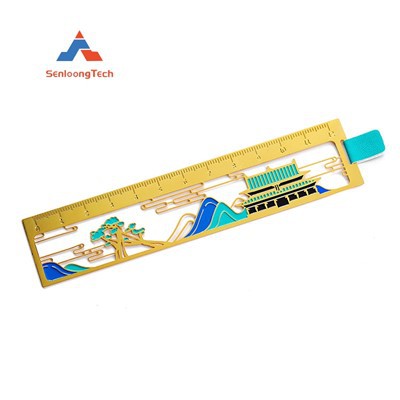

At present, the metal types involved in hardware etching on the market include copper plates, stainless steel plates, high carbon steel plates, aluminum plates, and zinc plates. The industries involved include printing, home appliances, electronic communication, floor embossing, die-cutting, architectural decoration, elevator decoration, leather and weaving embossing.

Etching principle

Etching, also known as photochemical etching, refers to the process of removing the protective film from the area to be etched through exposure, plate making, and development. During etching, it comes into contact with a chemical solution to achieve the effect of dissolving and corroding, forming concave convex or hollow shapes.

On a metal etching machine, it is a method of processing products by first protecting the required cover plate with screen printing or screen printing substrate, then chemically or electrochemically corroding off the unnecessary parts, and finally returning the protective film.

The metal etching machine is a crucial step in the production of signs, plates, metal crafts, metal prints, and processes. The first application of industrial technology was on the printed version of the Silk Road, but due to the dense threads of the Silk Road, processing would be difficult to achieve. The properties of different metals will change, and the precision of the etched pattern will vary with different etching depths. The etching method involves different compositions of etchants, and the photosensitive and corrosion-resistant materials will also undergo changes.