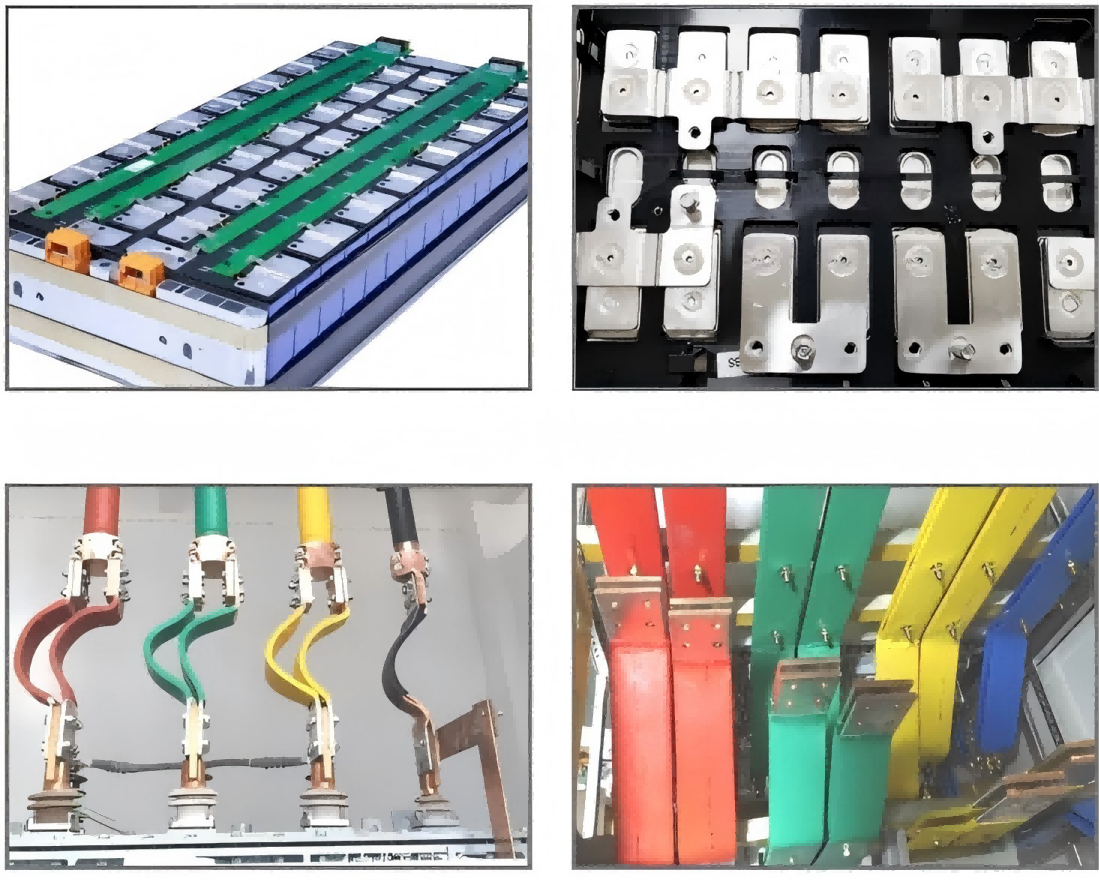

Aluminum Busbar For New Energy Vehicle

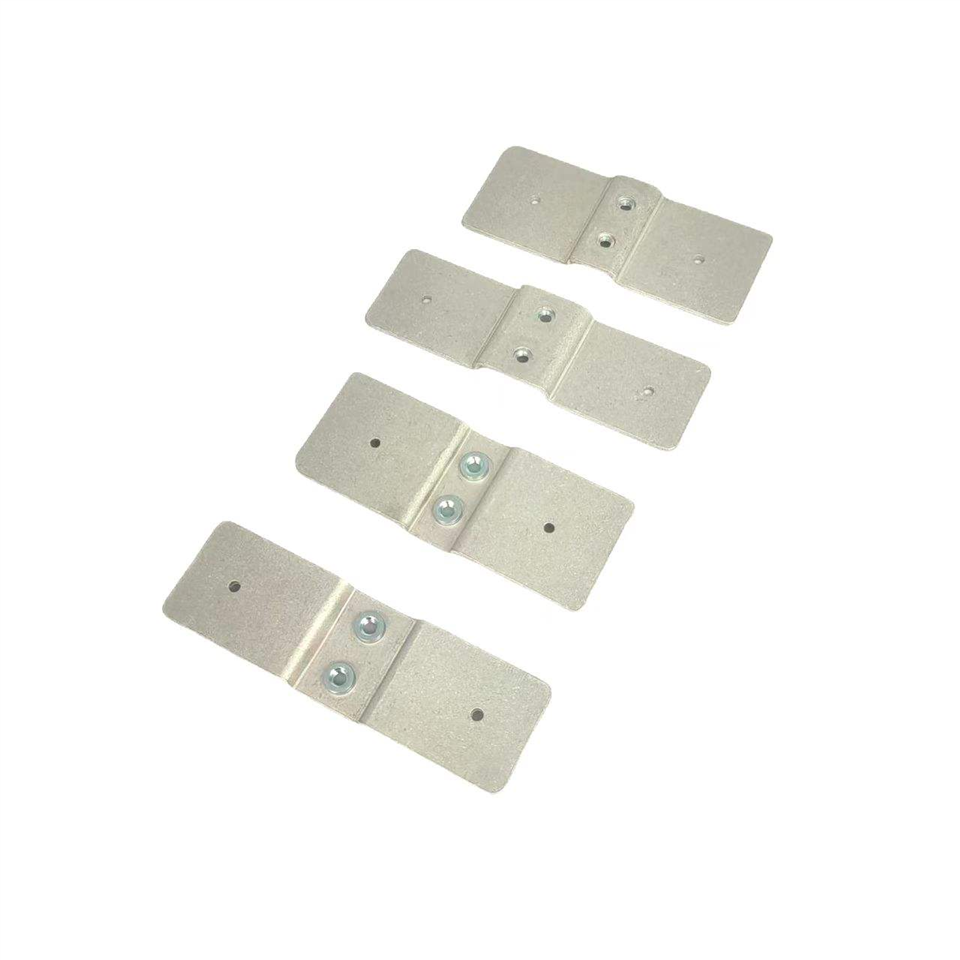

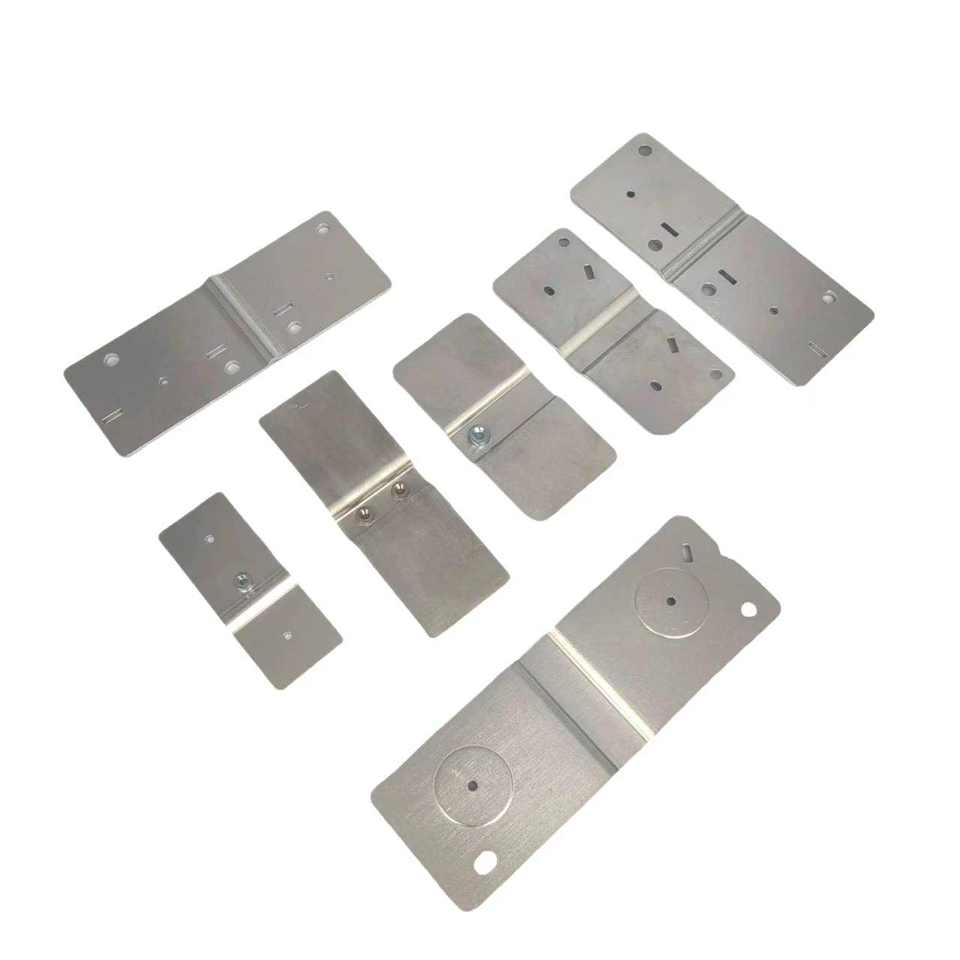

▲Product Name:Flat laminated aluminium busbar

▲Material:Aluminum

▲Size:Customized Size

▲Application:New energy vehicle batteries and others

▲OEM:OEM Service Provided

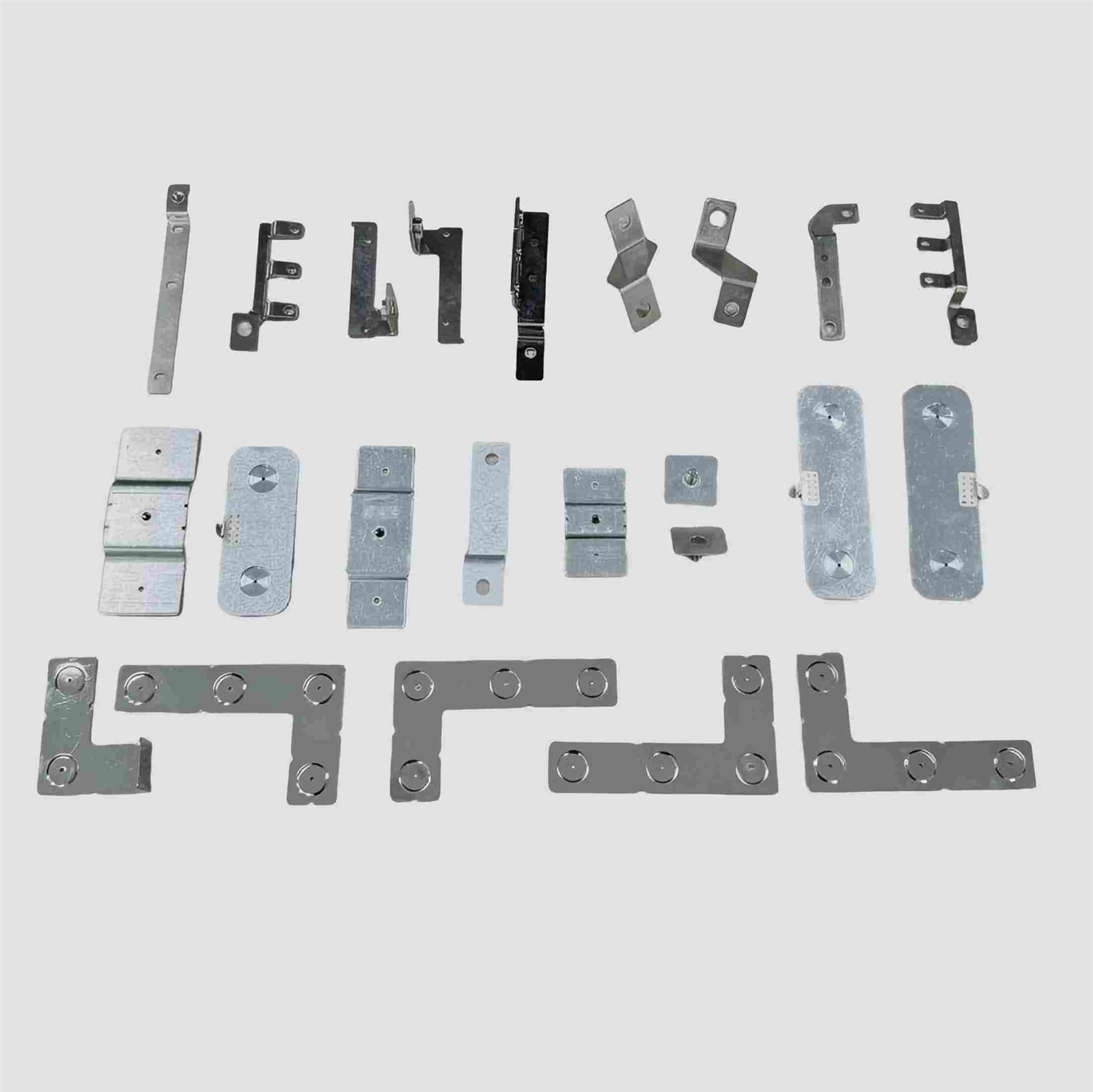

▲Processing Method:Stamping, bending, welding, electroplating

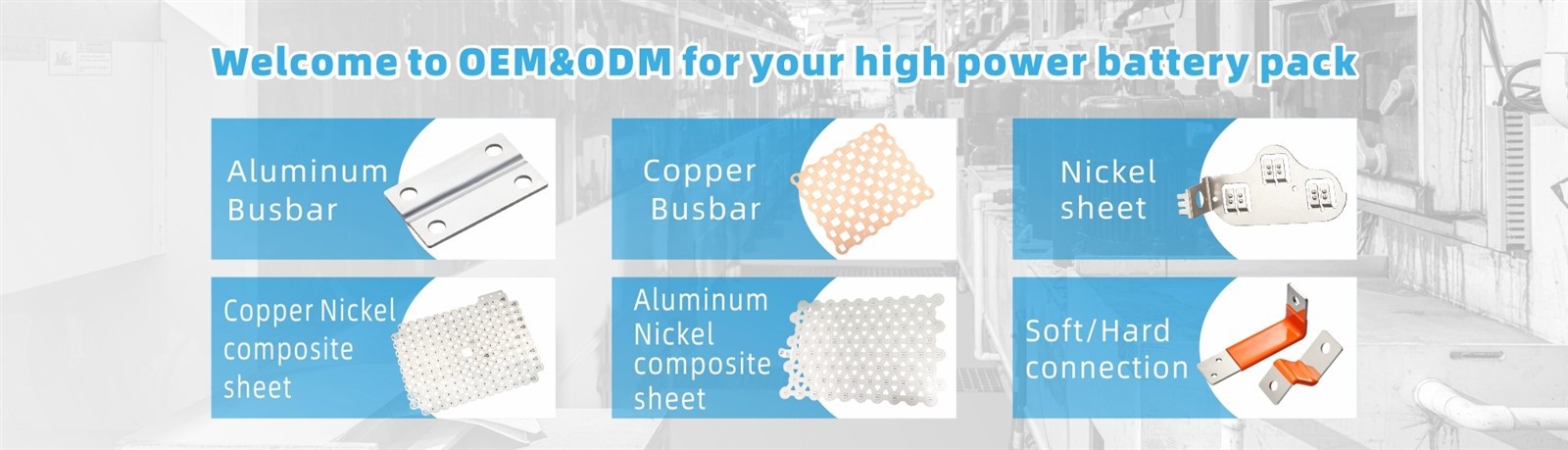

Customized aluminum busbar | High performance electrical connection solution for new energy vehicles

Senloong is an OEM/ODM custom manufacturer of aluminum busbars specializing in high-voltage electrical systems for new energy vehicles. We provide full process services from structural design, current simulation, precision machining, surface treatment to assembly testing.

Product coverage:

Power battery pack internal busbar (module to module/module to module connection)

High voltage distribution unit (PDU) integrated busbar

Motor controller (inverter) stacked busbar

Charging system busbar

Battery Management System (BMS) Sampling Bus

| Product Type | Custom New Energy Aluminum Busbar for Vehicle |

| Materials | Aluminum 1060, 1070, 6061, 6063, etc |

| Thickness | 0.8mm -6.0mm |

| Connection methods | laser welding, ultrasonic welding, bolt connection, HSD crimping, stud welding |

| Insulation treatment | powder coating (epoxy/polyester), PA/PP injection molding, PET film, silicone sleeve |

| Electrical performance | DC resistance deviation ≤ ± 3%, insulation resistance ≥ 100M Ω @ 500VDC |

| Protection level | Insulation components can reach IP67 |

| Accuracy tolerance | contour/hole position: ± 0.1mm; flatness: ≤ 0.2mm/100mm |

Application scenarios

▲Electric vehicles/hybrid vehicles (EV/HEV/PHEV): internal connections of battery pack, main positive and negative busbars, fast charging circuit

▲Fuel Cell Vehicle (FCEV): Stack Connection, DC/DC Module

▲Energy Storage System (ESS): Connection between battery clusters, combiner cabinet

▲Electric construction machinery: connection between high-power motor and battery

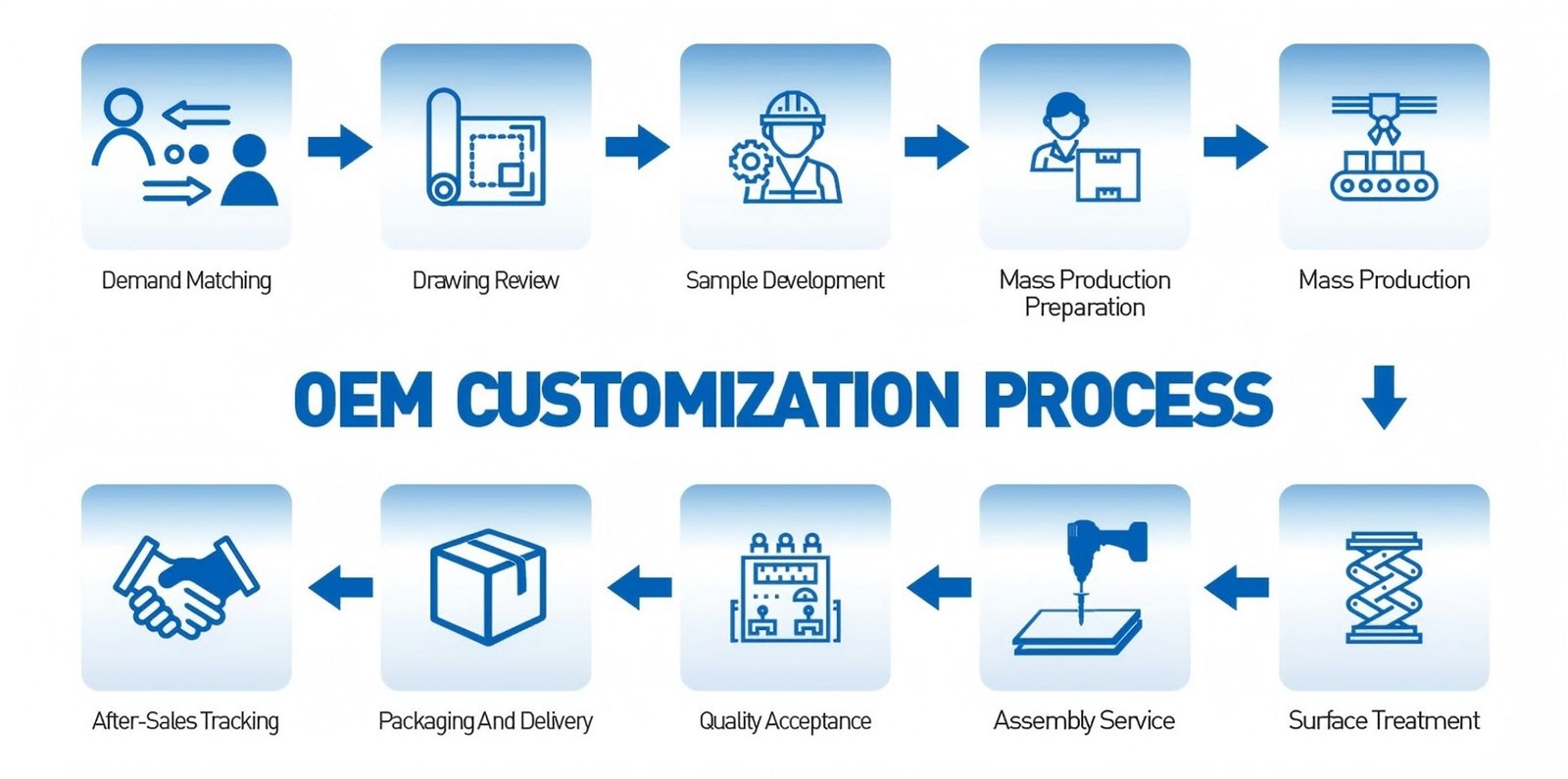

Customized cooperation process

▲1: Requirement Definition and Evaluation

You provide: electrical schematic, 3D digital model (STEP/IGES), technical requirements (current, voltage, temperature, vibration level), target cost and output.

We output: preliminary feasibility analysis, process route, and estimated quotation.

▲2: Collaborative Design and Simulation

The engineering teams of both parties work together to complete detailed structural design, electrical/thermal simulation optimization, and DFM review, and freeze the drawings.

▲3: Prototype Production and Validation

We produce functional prototype samples and provide first sample testing reports (dimensions, resistance, insulation, etc.). We support you in completing bench testing and DV verification.

▲4: Small Batch Production and Process Validation (PV)

Establish a stable production process, provide PPAP production part approval program file package, and conduct small-scale production for production line validation.

▲5: Mass production and continuous supply

Initiate fully automated or semi automated production lines, implement strict process quality control (SPC), and ensure long-term, stable, and reliable delivery.

FAQ

Q: How long does it take from drawings to obtaining a quotation?

A: We promise to provide a preliminary quotation within 24 hours for standard inquiries that provide complete 3D models and technical requirements. For complex projects that require simulation analysis or design optimization, we will provide a detailed project evaluation report and timeline within 48 hours.

Q: What is the minimum order quantity (MOQ)? Do you support mixed production scheduling?

A: There are no MOQ restrictions for the prototype and sample stages. For mass production, the economic batch size is usually 300-500 pieces, depending on the complexity of the product. We support mixed production scheduling, which allows you to combine multiple components for production to reduce your individual cost and minimum order threshold.

Q: What is the standard delivery cycle? How to ensure on-time delivery?

A: The standard delivery cycle for mass production orders is 4-6 weeks (from order confirmation, material procurement to finished product shipment). We use an Advanced Planning and Scheduling (APS) system to monitor material and production progress in real-time. Your dedicated project manager will proactively update the order status every week, and any potential delays will be alerted in advance and synchronized with solutions.

Q: Does your customization process support remote collaboration?

A: Yes, this is our standard working mode. We share design files, simulation reports, and inspection data with you through an encrypted collaboration platform. You can review the progress online at any time and make an appointment for "video live factory inspection" or "online first article inspection (FAI)" to ensure smooth communication.

Hot Tags: aluminum busbar for new energy vehicle, China aluminum busbar for new energy vehicle manufacturers, suppliers, factory

Send Inquiry