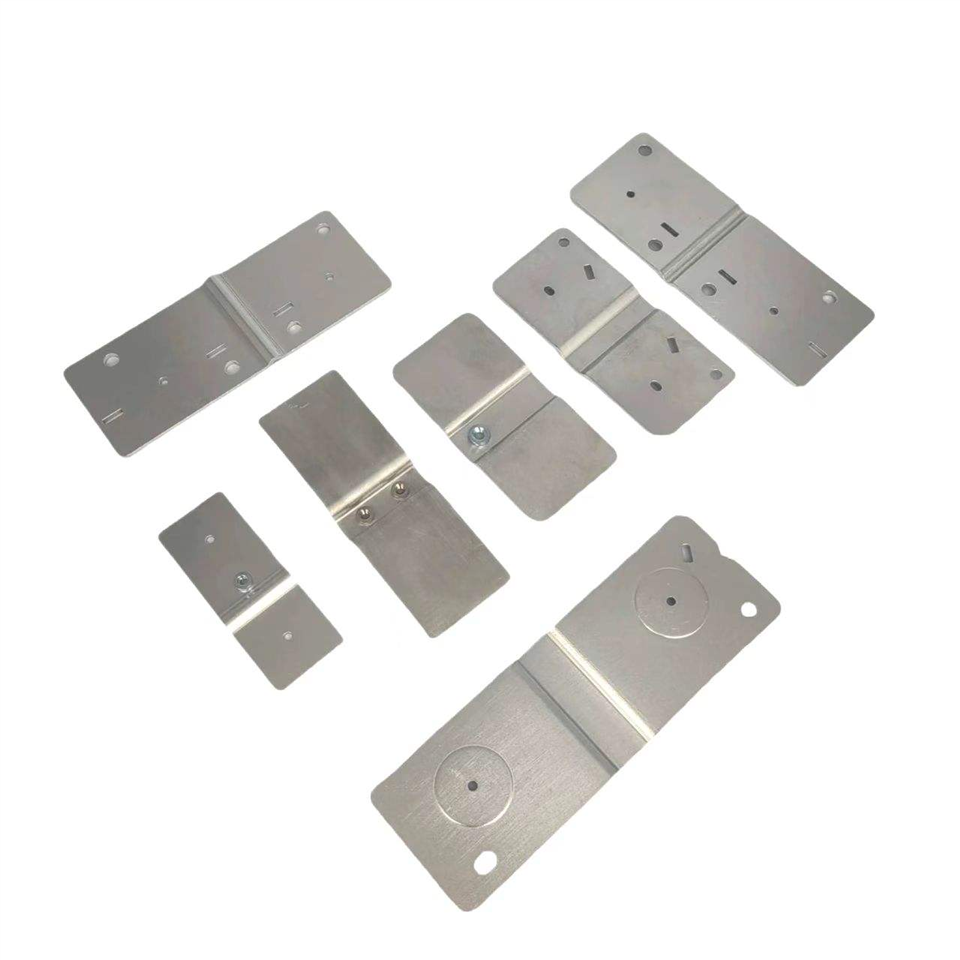

Aluminum Busbar For Energy Storage Batteries

▲Brand Name:Senloong

▲Model Number:Aluminum Busbar for Energy Storage Batteries

▲Place of Origin:Zhuhai, China

▲Material:Aluminum

▲Thickness:1.5mm 2mm

▲Width:25mm 30mm 35mm 40mm.....

▲Length:OEM

▲Application:Prismatic battery pack

▲MOQ:100pcs

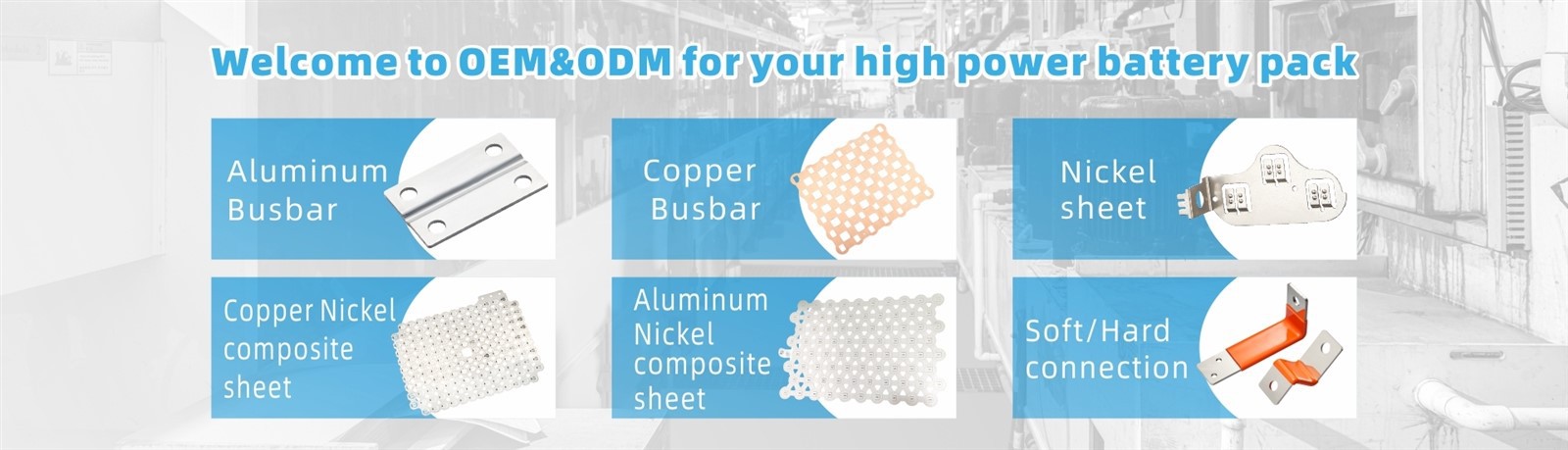

Customized Aluminum Row Product Text: Energy Storage Battery Specific Solution

Senloong specializes in producing high-performance customized aluminum bars, specifically designed for energy storage battery systems. As a customized manufacturer of aluminum bars, we deeply understand the stringent requirements of modern energy storage systems for conductivity, thermal management, and long-term reliability. Our aluminum busbar products are made of high-quality aluminum and processed with precision technology to provide efficient, safe, and customizable electrical connection solutions for your battery modules, PACKs, and system integration.

Whether you need sample trial production or large-scale production, we can provide one-stop service from design support to bulk delivery.

| Product name | Aluminum Busbar for Energy Storage Batteries |

| Application | Automotive, Wire Connection, Power etc |

| Material | Aluminum |

| Surface treatment | Anodization, Eletro plating, Oxide, |

| Process | Stamping and bending |

| Equipment | Punching machine and bending machine |

| Tolerance | 0.05- +/-0.1mm |

| Service | Customized OEM ODM Stamping and bending Machining |

| Packing | Customers'requirements |

| Certification | ISO9001 |

Core Features

▲1. Excellent conductivity performance

Using high-purity aluminum materials such as 1060 and 1070 (purity ≥ 99.6%), with a conductivity of up to 62% IACS

Special surface treatment process reduces contact resistance and improves overall energy efficiency

Optimize cross-sectional design to ensure uniform current distribution and reduce the generation of hotspots

▲2. Precision thermal management design

Integrated heat dissipation structure design effectively reduces temperature rise at connection points

Optional thermal interface material (TIM) to enhance heat dissipation efficiency

Thermal simulation support ensures stable operation of the system in high-temperature environments

▲3. Secure and reliable connection

Seismic design, with a vibration resistance level of up to 10-2000Hz/15G

Fire resistance meets UL94 V-0 standard

Corrosion resistant surface treatment, suitable for various harsh environments

Strict insulation protection design to prevent short circuit risks

▲4. Flexible customization capability

Support non-standard designs of any shape, size, and structure

Multiple surface treatment options: anodizing, electroless nickel plating, passivation, etc

Can integrate auxiliary functions such as sensor installation positions and fixed hole positions

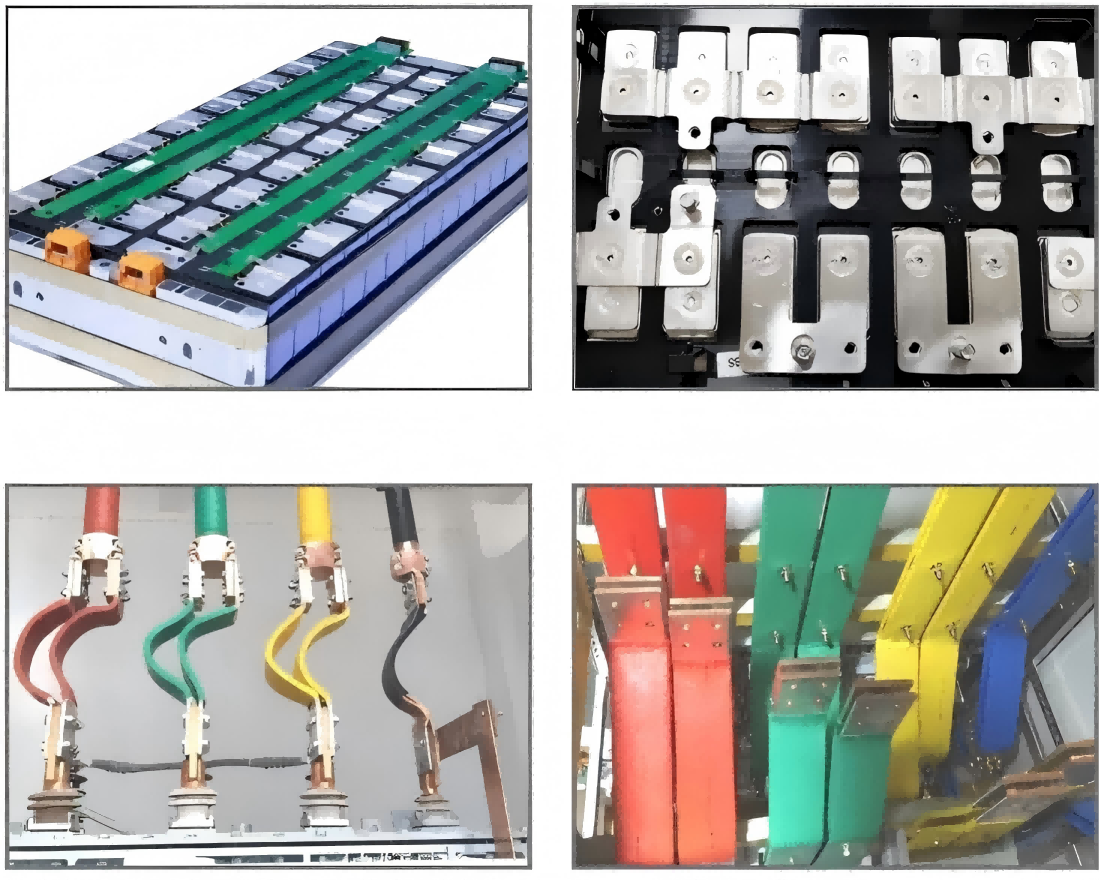

Application scenarios

▲Large energy storage power station: battery connection for grid peak shaving, frequency regulation, and backup power system

▲Industrial and commercial energy storage: backup power supply and energy consumption management for factories, shopping malls, and data centers

▲Household energy storage system: integrated solution for household photovoltaic energy storage

▲Mobile energy storage devices: emergency power vehicles, portable energy storage devices

▲Electric Vehicle Charging Station: Electrical Connection for Supporting Energy Storage System

▲Backup power supply for communication base station: 5G base station, communication room energy storage system

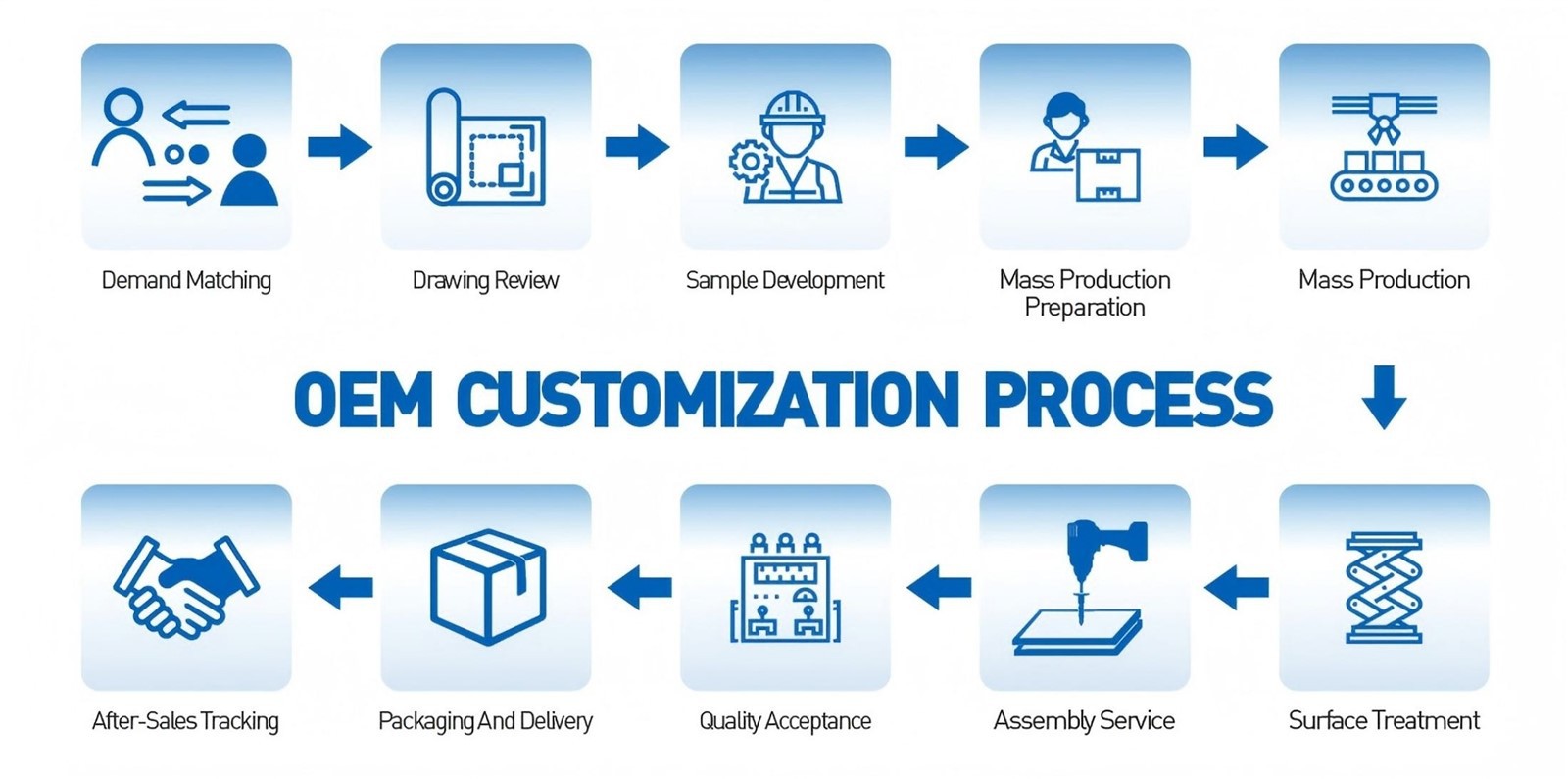

customization process

▲Requirement docking (1-2 days)

You provide:

Drawings/3D models/sample photos - Current parameters and size requirements - Surface treatment and quantity requirements

We provide feedback:

Feasibility Assessment of Process - Preliminary Quotation and Delivery Time - Material Proposal Proposal

▲Design confirmation (2-5 days)

3D modeling and engineering drawing production - process plan determination (stamping/bending/welding) - drawing customer confirmation and signature

Deliverables: Formal Processing Drawings

▲Sample production (5-8 days)

Quick mold/tooling preparation - sample trial production (3-5 pieces) - basic testing (size+conductivity) - sample delivery for customer verification

Deliverables: Physical samples+testing reports

▲Batch production (scheduling according to quantity)

Raw material procurement - Large scale production and process inspection - Final testing and anti-oxidation packaging - Timely delivery and provision of quality assurance certificate

Deliverables: Batch products+complete quality documents

FAQ

Q: What is the minimum order quantity for customized aluminum bars?

A: We offer flexible order solutions: sample orders of 1-10 pieces are sufficient; Small batch orders starting from 100 pieces; Large scale production has no minimum limit, and the larger the quantity, the more favorable the unit price.

Q: How long does it usually take from design to delivery?

A: The sample stage usually takes 2-3 weeks, including design, sample production, and testing. The batch production time depends on the complexity and quantity of the order, and regular orders can be completed in 3-4 weeks.

Q: How to ensure compatibility between aluminum bars and battery systems?

A: We provide free design consulting services and require you to provide detailed parameters, installation space dimensions, current requirements, and other information for the battery module/PACK. We can also participate in your early design phase after signing the NDA.

Q: What are the advantages of aluminum bars compared to copper bars?

A: Aluminum bars have advantages such as light weight (1/3 of copper), low cost, and good corrosion resistance. Through optimized design and surface treatment, our aluminum busbar's conductivity can meet the needs of the vast majority of energy storage applications.

Q: What quality assurance do you provide?

A: We provide: 1) Material composition report; 2) Dimensional inspection report; 3) Conductivity test report; 4) Salt spray test report (if required); 5) Insulation and voltage withstand test report. And can cooperate with customers for third-party testing.

Q: How to deal with the oxidation and corrosion problems of aluminum bars?

A: We offer multiple surface treatment solutions: anodizing can form a dense oxide layer; Chemical nickel plating provides better corrosion resistance and weldability; Special treatments such as conductive coatings can also be used.

Q: Does it support integrated temperature monitoring function?

A: Yes, we can design aluminum bars that integrate temperature sensor installation positions, support multiple sensors such as NTC and PT1000, and provide signal line extraction solutions.

Get your exclusive plan now

Provide the following information to receive free design solutions and quotes within 24 hours:

Application scenarios (energy storage type/power level)

Current requirements (rated/peak)

Installation space size limitation

Connection method (bolt/welding/crimping)

Surface treatment requirements

Expected demand quantity

Contact Us

Phone:+8618088822595

Email: sales@senloong.com

Hot Tags: aluminum busbar for energy storage batteries, China aluminum busbar for energy storage batteries manufacturers, suppliers, factory

Send Inquiry