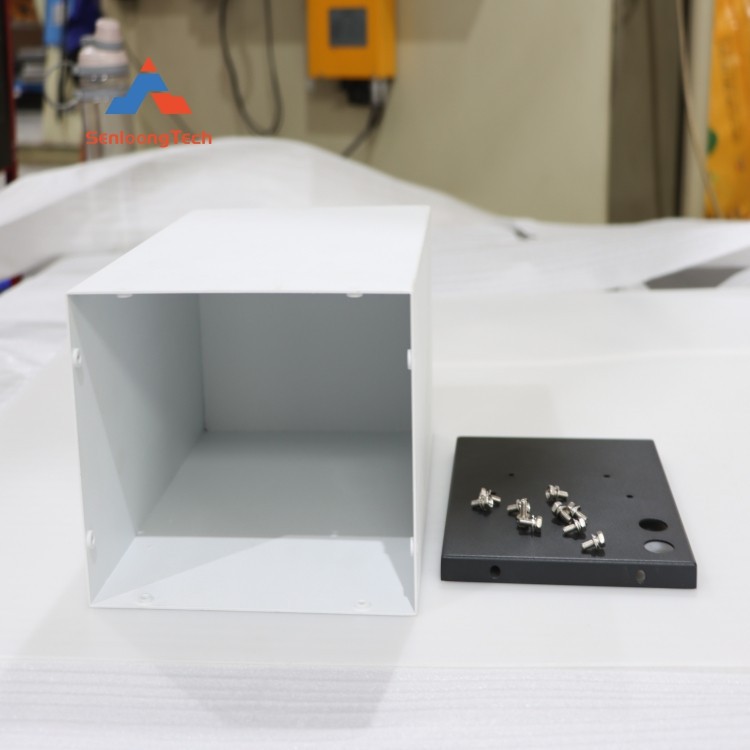

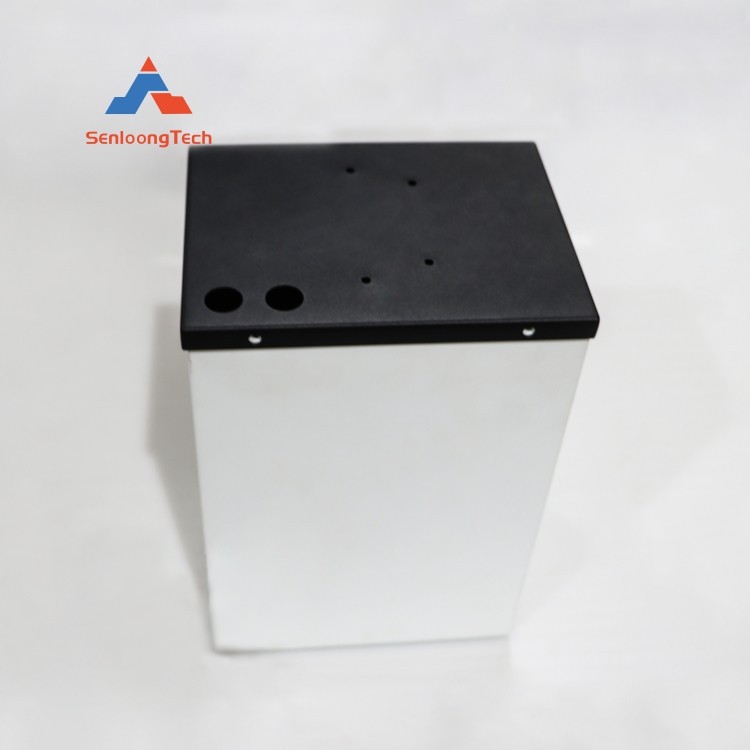

Lifepo4 Battery Plastic Case

✦Place of origin: Guangdong, China

✦Materials: stainless steel, steel, aluminum, brass, copper

✦Battery box size: customized

✦brand name: SENLOONG

✦model number: Lifepo4 battery case

✦Color: Black/white

✦OEM/ODM: Support

Products Description

The Lifepo4 Battery Plastic Case produced by our company is specifically designed for lithium iron phosphate batteries. It is a high-performance protective casing that mainly wraps the battery cells for protection. This casing is usually made of high-strength, heat-resistant, and chemically resistant plastic, which can adapt to the battery's use in various environments. Its mechanical strength and impact resistance are both quite good, and it is produced according to design requirements with particularly accurate dimensions. As the outer layer protection of the battery, this plastic shell has excellent insulation performance, which can effectively prevent battery leakage and ensure safe use. It is suitable for energy storage systems, electric tools, new energy vehicles, solar equipment and other fields.

|

Packing: |

Carton |

|

Usage: |

Battery energy storage |

|

OEM & ODM : |

Support Customize |

|

Quality: |

A+ Grade 100% |

|

brand name: |

SENLOONG |

|

Place of origin: |

Guangdong, China |

|

model number: |

Lifepo4 battery case |

|

Color: |

Customizable colors |

|

MOQ: |

1 Piece |

|

Delivery Time: |

3-6 Days |

Application scenarios

- Electric vehicles

In the field of electric vehicles, this type of battery box has been widely used due to its high safety and long cycle life.

- Energy storage system

In energy storage systems, such as household energy storage and industrial energy storage, the safety and stability of batteries can be ensured during long-term use.

- Consumer electronics products

For some small consumer electronics products, this battery box meets the demand for lightweight and miniaturized products.

Core features of the product

● High protection performance

Waterproof and dustproof: IP65/IP67 protection level, effectively resisting water vapor, dust, and chemical corrosion.

● Lightweight design

Compared to metal casings, it reduces weight by 30% to 50%, lowers overall equipment load, and improves energy efficiency.

● High temperature resistance and weather resistance

Working temperature range: -30 ° C to+80 ° C, suitable for extreme weather environments.

● Insulation and safety

Completely insulated material, eliminating the risk of electrical leakage, and complying with electrical safety standards such as UL/IEC.

● Customized structure

Support modular splicing design, flexibly adapt to different battery series and parallel layouts.

● Environmentally friendly materials

Compliant with RoHS/REACH environmental standards and recyclable.

Company introduction

Zhuhai Senloong Electronics Co., Ltd. is a manufacturer of customized battery boxes. Our company has advanced laser cutting, stamping, sheet metal processing production lines in China, as well as dozens of auxiliary supporting equipment. The production base covers a total area of over 10000 square meters. Has strong abilities in product quality and variety, structural design, after-sales service, and other aspects.

Our company's main products include sheet metal parts processing, sheet metal boxes, battery boxes, hardware, electronic components, battery connectors, etc. Our products are widely used in various industries such as postal and telecommunications, industrial control, home energy storage, power, medical equipment, outdoor power supply, etc.

We promise to deliver the highest quality products and prompt services to you, while ensuring the stability of delivery time. We are committed to providing you with the most valuable and competitive products.

During the exhibition, we successfully held multiple industry forums and technical seminars, bringing together numerous industry experts and business representatives. This measure has created a high-quality platform for us to have in-depth communication and learning with peers, enabling us to gain insight into the latest developments in the industry and helping us provide more outstanding services to our customers.

We have successfully passed multiple authoritative certifications including CCC, CE, RoHS, and IEC, which cover the most basic and important requirements for product safety and quality in the global market. They comply with the necessary safety and quality standards in the global market, providing users with peace of mind and reliability assurance.

Production process of lifepo4 battery plastic case

Based on the specific requirements of the customer for the plastic casing of LiFePO4 batteries, use professional design software to carry out 3D design work and generate accurate design drawings.

Using CNC milling and other processing techniques, the mold core and frame are finely processed to ensure the accuracy and quality of the mold.

Assemble and debug the processed mold core and mold frame. At the same time, necessary surface treatments such as painting, electroplating, etc. should be carried out on the mold.

Select suitable plastic materials and dry them to remove moisture to ensure the quality of injection molding.

Adjust various parameters of the injection molding machine, such as temperature, pressure, speed, etc., based on the characteristics of the plastic material and the design requirements of the plastic shell.

Dry plastic raw materials are added to the hopper of the injection molding machine, cooled and solidified, and then the mold is opened to remove the molded plastic shell.

Post process the formed plastic shell and inspect it at the same time.

Delivery and Transportation

- Packaging and Shipping: Packaging products that have passed inspection, usually using PP bags and cardboard boxes or pallets for packaging. Then, put the packaged products into storage and wait for shipment.

- Transportation modes: mainly including ocean transportation, air transportation, railway transportation, road transportation, and multimodal transportation.

- Conventional payment methods

1. Advance payment+final payment: After the contract is signed, a deposit of 30% to 50% should be paid, and the remaining balance should be settled before shipment or after inspection (applicable to customized products).

2. Letter of Credit (L/C): Commonly used in international trade, it reduces risk through bank guarantees and requires clear presentation terms (such as bills of lading and quality inspection reports).

3. Cash on Delivery (COD): It can support domestic small batch orders, but requires additional deposits or credit checks.

4. Platform transactions (such as Alibaba International Station): support Alipay PayPal, telegraphic transfer (T/T) and other methods to ensure capital security.

FAQ

Q: Can your product be customized?

A: Considering the differences in voltage, frequency, and other special transformer products in different countries and regions, our products can be customized according to your requirements.

Q: What are the well-known clients of the company?

A: We have established long-term cooperative relationships with several well-known domestic and foreign enterprises, with clients covering industries such as new energy, electric vehicles, and energy storage systems.

Q: Do you welcome new clients to cooperate?

A: Yes, we welcome new customers to cooperate and provide customized solutions and high-quality services.

Q: How to become your long-term partner?

A: We welcome long-term cooperation. You can contact our sales team by email or phone to learn about the details of the cooperation.

Q: How long is the development cycle for customized battery boxes?

A: The development cycle depends on the complexity of the design, usually completing the design and sample production within 2-4 weeks after receiving the requirements.

Q: Does it support the production of small batches or complex processes?

A: Yes, our equipment has strong flexibility and supports small batch customization and production with complex processes.

Hot Tags: lifepo4 battery plastic case, China lifepo4 battery plastic case manufacturers, suppliers, factory, aluminum etching, Black Metal Speaker Grill, , decorative metal etching, 2P 21700 Nickel Strip, 6v battery box

Send Inquiry