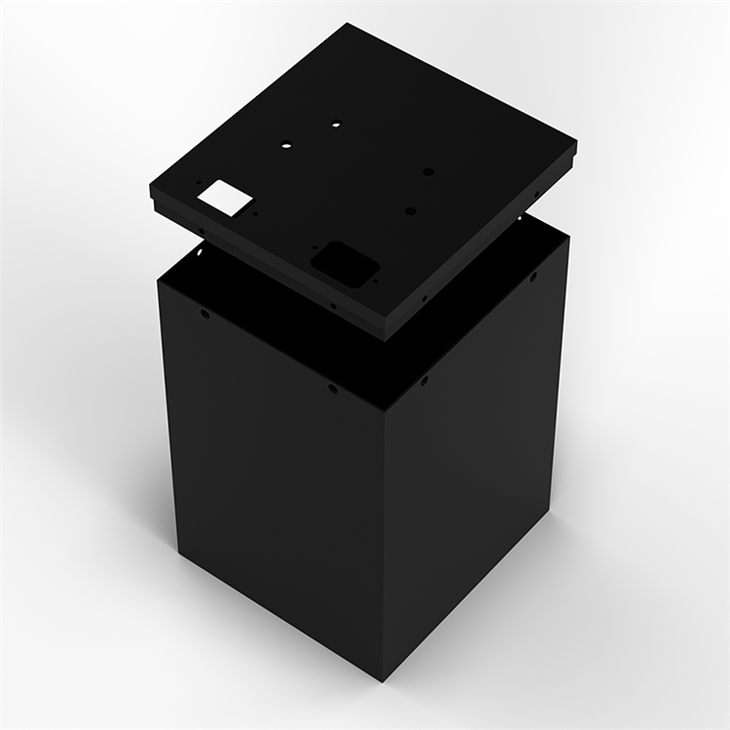

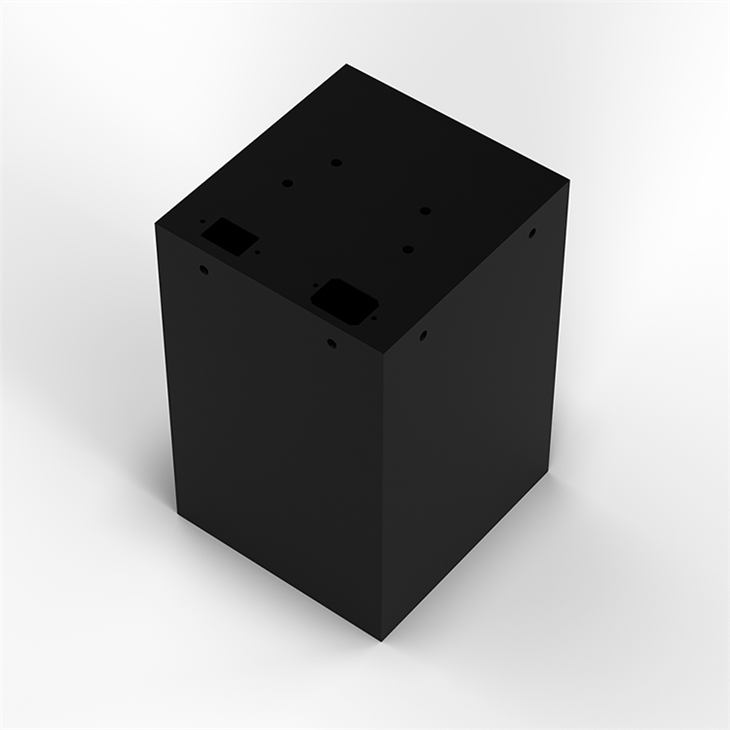

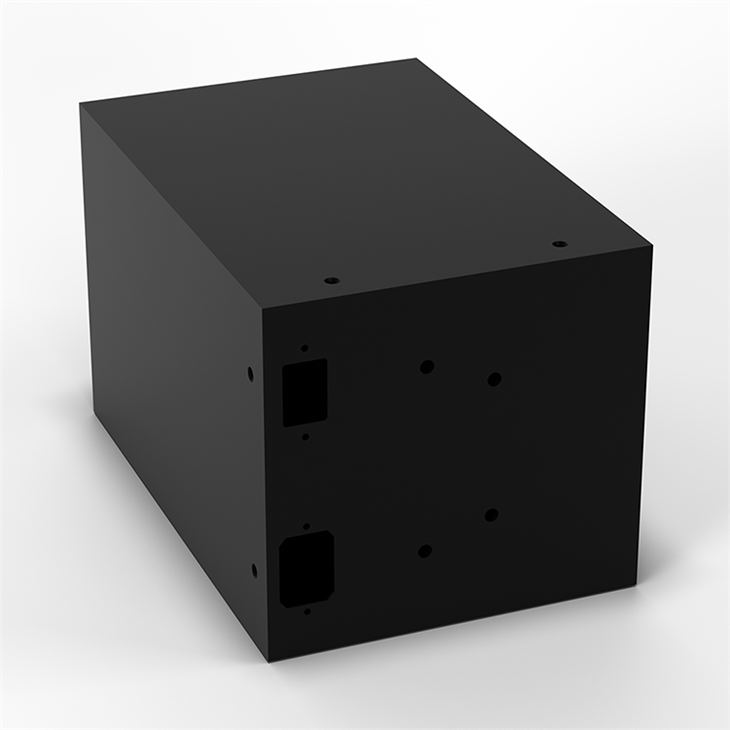

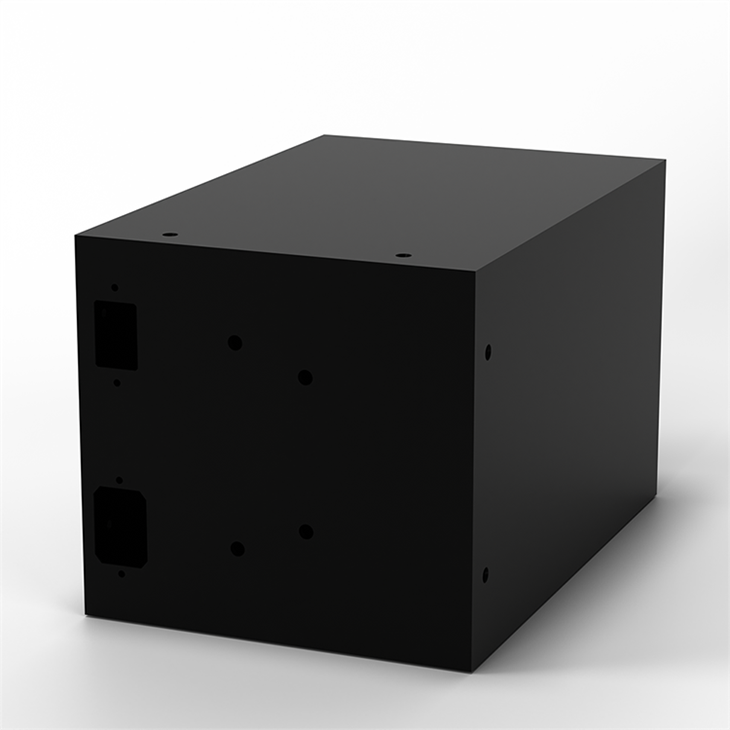

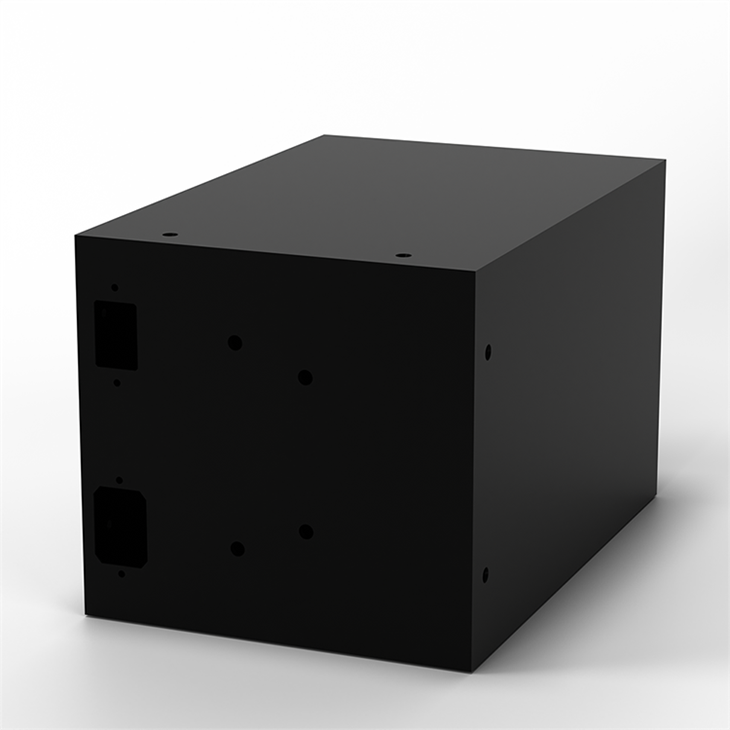

Enclosure Box Sheet Metal Fabrication

▲ Product Name: DIY metal box enclosure

▲ Specifications: Customized or according to your drawings.

▲ Packaging: cardboard boxes or according to customer needs

▲ Function: Strong dust resistance

▲ Experience: 20 years

▲ Example: Supporting Examples

Precision sheet metal processing metal shell box --- professional protection solution

Precision sheet metal processing metal shell box - professional protection solution

We specialize in producing various types of sheet metal shell boxes, using high-precision laser cutting, CNC bending, welding, and surface treatment processes to create high-strength, corrosion-resistant, aesthetically pleasing, and durable industrial grade chassis, control boxes, electrical boxes, and equipment protective shells. Widely used in fields such as power and electrical, communication equipment, industrial automation, medical devices, military equipment, etc., providing safe and reliable protection for precision instruments. We have a large-scale sheet metal production line to ensure timely delivery and cost advantages, support OEM services, and meet customers' personalized appearance needs.

Product parameter

|

Product Name: |

DIY metal sheet box enclosure |

|

Model: |

Customized battery metal box |

|

Surface treatment: |

anodizing, polishing, heat treatment, oxidation, laser engraving logo |

|

Minimum order quantity: |

Accepting small orders |

|

Payment methods: |

wire transfer or PayPal |

|

Features: |

No burrs, anti-corrosion, no deformation |

|

Certification: |

CE, TUV, ISO9001, ISO14001, OHSAS18001 |

|

Application: |

Home energy storage/solar energy storage/power system |

|

Sample service: |

Provided |

|

Customization: |

Accepting cabinet customization |

typical scenarios

✔ Industrial Control - PLC Control Cabinet, Inverter Cabinet, Automation Equipment Shell

✔ Communication equipment -5G base station chassis, server cabinets, fiber optic terminal boxes

✔ New energy power - photovoltaic inverter box, battery casing, distribution cabinet

✔ Medical and Military Industry - Instrument Protection Boxes, Electromagnetic Shielding Boxes, Military Equipment Enclosures

Core advantages of the product

Selection of high-quality materials

High strength, economical and practical, surface can be sprayed/galvanized for rust prevention.

Flexible customized design

Support customization of display screens, buttons, and heat dissipation holes of various sizes.

Sealing protection:

Optional waterproof adhesive strip, with a protection level of up to IP65/IP67.

Production process flow

1. Laser cutting → 2 CNC bending → 3 Stamping/Drilling → 4 Welding Forming → 5 Surface treatment → 6 Assembly quality inspection

*Precision manufacturing process

- Laser cutting: high-precision cutting of ± 0.1mm, smooth and burr free incision.

- CNC bending: precise molding, bending angle error ≤ 0.5 °, ensuring that the box is tightly fitted.

- Welding reinforcement: using argon arc welding/laser welding, the weld seam is firm and the deformation is small.

- Surface treatment: spray coating, anodizing, electroplating, etc., to enhance weather resistance and aesthetics.

Customized Process

1. Requirement matching → 2. Drawing review → 3. Sample development → 4. Preparation for large-scale production → 5 Mass production → 6. Surface treatment → 7. Assembly services → 8 Quality acceptance → 9. Packaging and delivery → 10. After sales tracking

company profile

We have a large number of high-precision processing equipment. It makes our processing quality better and our service more competitive.

-

CNC workshops

-

Large laser cutting machine

-

Sheet metal bending machine

-

Forging Machine

-

Laser engraving equipment

-

Wire cutting machines

Quick delivery

Various logistics modes are available

Free sample

Products sample are available

Secure payment

100% secure payment

24/7 Support

Dedicated support

corporate culture

By carrying out a series of activities and team building, the company not only creates a harmonious corporate atmosphere, but also provides employees with opportunities to achieve their career goals and enhance their personal value, thus creating a people-oriented and harmonious corporate culture environment.

certificate and partner

We have corresponding material and production standard certifications, ISO 9001:2015 and IATF 16949:2016 quality system certifications,also have passed ROHS, CE, FCC, REACH, SVHC, etc.

Over the years, we have established long-term friendly cooperative relationships with many clients from all over the world.

brand trusted choice

We work closely with our agents/distributors, and we are committed to providing marketing support, technical support, training, sales channels and other full range of services to help each partner's career development.

package and transport

We provide comprehensive customized packaging services to meet customers' special packaging needs. Whether you want to display the brand logo on the packaging, require special sizes of packaging, or even have other personalized requirements, we can customize according to the detailed needs of our customers. Our goal is to ensure that packaging is not only practical, but also effectively showcases and identifies the brand.

Shipping:

✤ Domestic transportation: Less than truckload logistics/car transportation/express transportation

✤ International transportation: sea freight container/railway/air freight

✤ Parts can be transported through DHL/EMS/TNT/FedEx/UPS or other special methods.

✤ If you have no preference for courier companies, we will arrange for you.

fAQ

Hot Tags: enclosure box sheet metal fabrication, China enclosure box sheet metal fabrication manufacturers, suppliers, factory, software-grade metal box

Send Inquiry