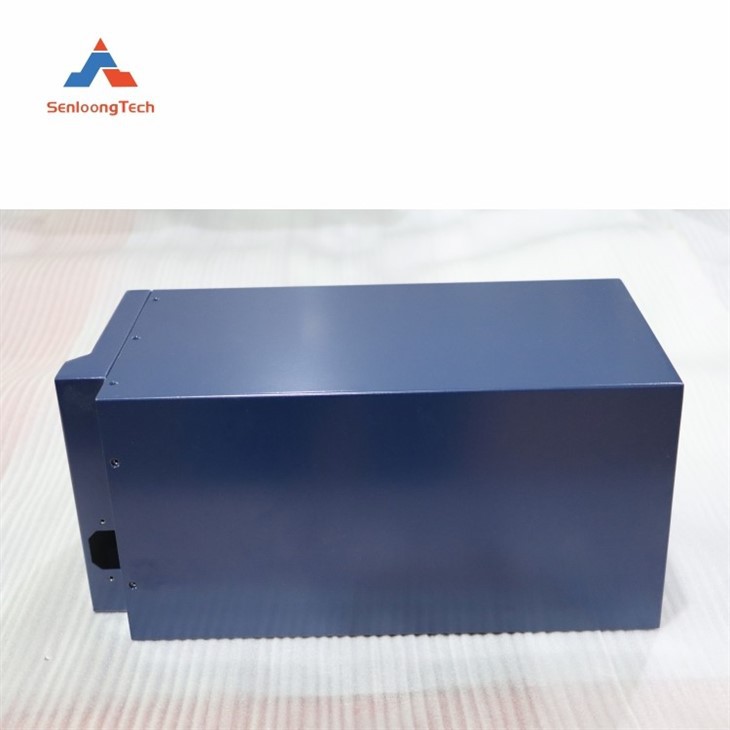

Aluminum Steel Sheet Metal Boxes

♚ Product Name: DIY Metal Battery Box

♚ External dimensions: customized

♚ Materials: stainless steel, aluminum. Steel, metal, etc.

♚ Minimum order quantity: Accepting small orders

♚ Industry: stamping, deep drawing, laser cutting, bending, welding, CNC, etc.

♚ Experience: 20 years

♚ Example: Supporting Examples

♚ Application: Home energy storage/solar energy storage/power system

Aluminum sheet metal boxes (boxes or chassis made from sheet metal processing) are widely used in multiple fields due to their lightweight, high strength, customizability, and high cost-effectiveness. Users can choose the appropriate model based on their capacity requirements, installation space, and budget, and we provide customized battery solutions for you. We strive to achieve precise matching in terms of size, material, and functional characteristics to meet the diverse usage scenarios and performance requirements of our users.

product parameters

|

Product type:

|

DIY Metal Battery Box

|

|

Logo:

|

Customized Logo

|

|

Surface treatment:

|

anodizing, powder coating, spray painting, natural treatment, electroplating

|

|

Accessories:

|

shell+bracket+nickel+wire |

|

Certification:

|

ROHS

|

|

Delivery time:

|

1-25 days after the order, prepayment based on product structure and quantity

|

|

Color and size:

|

can be customized according to needs

|

|

Service:

|

Customized OEM sheet metal service

|

|

Application areas:

|

household energy storage/solar energy storage/power systems

|

|

Cooperation mode:

|

You can purchase matching battery brackets or provide copper plate drawings, and we will process according to the drawings.

|

Product application

Electronic equipment chassis:

a protective shell for servers, industrial computers, and other equipment.

Power distribution system:

distribution cabinets, control boxes, meter boxes, etc.

Communication equipment:

5G base station casing, fiber optic terminal box, signal amplifier box.

Industrial control box:

PLC control cabinet, operation panel, sensor protection box.

Mechanical equipment casing:

automated production line equipment, machine tool control box.

Tool and instrument box:

portable testing equipment box, measuring instrument housing.

our advantage

We welcome OEM and ODM design and labeling to ensure that your unique requirements are met.

We use advanced production equipment and technology to ensure efficient production and high-quality output of our products.

We constantly innovate and develop to meet the ever-changing demands of the market.

We have a comprehensive supply chain management system to ensure the stability and timeliness of material supply.

Our professional team provides comprehensive consulting services and competitive solutions based on your needs.

company profile

Zhuhai Senloong Electronics Co., Ltd. is located in Guangdong, China. It has 20 years of professional industry production experience and a factory area of 11,000 square meters.

We support OEM/ODM; Fast production delivery (1~2 days) and NO MOQ; Daily production capacity 3kk pcs.

Mainly manufacturing nickel sheets, aluminum sheets, copper busbars, auto parts, mobile phones, computer hardware structural parts, speaker horn net, various etching filters, and hardware decoration etching products.

The industries involved include new energy storage, batteries, automobiles, motorcycles, computers, mobile phones, vacuum cleaners, coffee machines, electronic tools, medical equipment, aerospace, etc.

There are many types of process technologies, such as laser cutting, wire cutting, etching, stamping, spot welding, laser welding, CNC machine tools, molds, bending, nuts/screws rivets, screw drills, tape and lamination, etc.

20

+

Years of experience

36

%

TECHNICIANS & WORKERS

2578

+

SATISFIED CUSTOMERS

1984

+

completed projects

company exhibition

Recently, we have actively participated in new energy, automotive, and consumer electronics exhibitions held in Guangzhou, Shenzhen, Vietnam, and Hong Kong, showcasing our latest achievements in these fields.

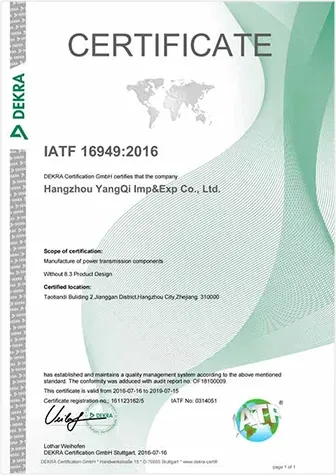

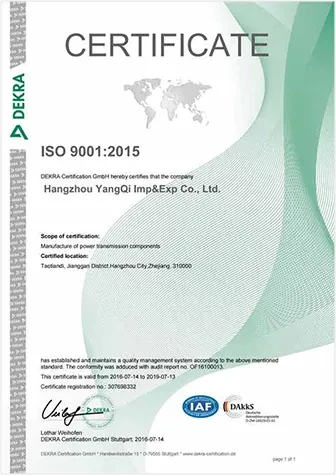

honor display

Through independent laboratory testing of 12 key indicators such as cycle life, energy density, and low-temperature discharge, the report can be publicly accessed to dispel customer technical doubts.

IATF 16949:2016

ISO 9001:2015

Environmental Management System Certificate

Our Service Processes

Pre-sales Consultancy

1

>>

Confirmation of order

2

>>

Production

3

>>

Multi-Channel Shipping

4

>>

Confirmation of recei

5

>>

After-sale Services

6

business partners

At Zhuhai Senlong Electronics Co., Ltd., we cooperate with well-known enterprises such as Samsung Electronics, Amphenol, Philips, Hisense, Huawei, etc. Our team not only focuses on current market demand, but also on future development trends.

Production process of sheet metal box

production process

The production process of sheet metal boxes usually includes material preparation, forming processing, connection technology, surface treatment, and quality inspection.

The main precautions are as follows:

Process sequence optimization:

Avoid situations where welding or spraying cannot be achieved after bending.

Deformation control:

Reduce welding and bending deformation through fixtures and perform necessary corrections.

Cost control:

Optimize unloading plans (such as regular edge cutting) to improve material utilization.

Here are some of the production equipment we have available:

package and delivery

We provide comprehensive customized packaging services to meet customers' special packaging needs. Whether you want to display the brand logo on the packaging, require special sizes of packaging, or even have other personalized requirements, we can customize according to the detailed needs of our customers. Our goal is to ensure that packaging is not only practical, but also effectively showcases and identifies the brand. Through this comprehensive packaging solution, we are committed to providing our customers with unparalleled peace of mind and convenience, ensuring that they feel our attention to detail and commitment to quality when they receive our products.

aftersales service

- Technical support: Provide free technical consultation to help customers solve problems during product use. Provide detailed product manuals and operating instructions.

- Accessory supply: Long term supply of original factory accessories to ensure the long-term stable operation of the product. The prices of accessories are open and transparent, providing fast shipping services.

- Regular Follow up: Regularly conduct phone or on-site visits to customers to understand product usage and solve problems in a timely manner.

do you have any question?

What can you buy from us?

The cutting surfaces on a vertical end mill bit (are for milling ) are on its sides , designed for cutting horizontally , a drill bit ( are for drilling ) cutting surface is at its tip , designed for cutting vertically downward .. you'll notice a end mill usually has a flat on the end of the bit .

Can you give me a discount?

The cutting surfaces on a vertical end mill bit (are for milling ) are on its sides , designed for cutting horizontally , a drill bit ( are for drilling ) cutting surface is at its tip , designed for cutting vertically downward .. you'll notice a end mill usually has a flat on the end of the bit .

What should I do if I am unable to meet your minimum order quantity?

The cutting surfaces on a vertical end mill bit (are for milling ) are on its sides , designed for cutting horizontally , a drill bit ( are for drilling ) cutting surface is at its tip , designed for cutting vertically downward .. you'll notice a end mill usually has a flat on the end of the bit .

What are the advantages that distinguish it from others?

The cutting surfaces on a vertical end mill bit (are for milling ) are on its sides , designed for cutting horizontally , a drill bit ( are for drilling ) cutting surface is at its tip , designed for cutting vertically downward .. you'll notice a end mill usually has a flat on the end of the bit .

Hot Tags: aluminum steel sheet metal boxes, China aluminum steel sheet metal boxes manufacturers, suppliers, factory, software-grade metal box

Send Inquiry