Etching Metal Flat Crafts

1. Process: Advanced chemical or laser etching techniques are used.

2. Material: Supports various metal materials such as stainless steel, copper, aluminum, brass, etc.

3. Customization: Patterns, text, logos, etc. can be customized according to customer needs.

4. Application: Suitable for multiple fields such as new energy industry, home decoration, gift customization, corporate promotion, art collection, etc.

5. Features: Environmentally friendly and durable, the metal material has corrosion resistance and oxidation resistance, ensuring the long-term preservation of handicrafts.

6. Surface treatment: Provides various surface treatment processes such as polishing, electroplating, oxidation, etc.

7. High cost-effectiveness: Compared to traditional carving techniques, etching techniques have lower costs and higher efficiency.

8. Fast delivery: With mature production processes and a professional team, we ensure high-quality and efficient delivery.

Etching metal flat crafts

The material of metal etching crafts is usually selected from high-quality metals such as stainless steel, copper, aluminum, brass, etc. These materials not only have a natural metallic luster, but also present rich layering and three-dimensional effects through etching processes. Designers can create various patterns through hand drawn or digital tools, including geometric shapes, natural landscapes, cultural symbols, personalized text, etc., to meet the needs of different scenarios and customers. Whether it's a minimalist modern style or a retro classic style, metal etched crafts can be perfectly presented.

The process of making metal etched flat crafts includes multiple steps such as design, material processing, pattern transfer, etching, cleaning, and post-processing. Firstly, the designer draws or digitizes the pattern, and then transfers it to the metal surface coated with a corrosion-resistant layer through photolithography technology. Next, the pattern is precisely carved using chemical etching solution or laser etching technology, and finally the finished product is made more beautiful and durable through cleaning and surface treatment (such as polishing, electroplating, or coating). Each handicraft is carefully polished to ensure clear patterns and smooth edges,

showcasing a high level of craftsmanship.

|

Parameter |

Typical Range/Options |

|

Material Type |

Stainless steel, copper, aluminum, brass, titanium |

|

Thickness |

0.01 mm to 2 mm |

|

Resolution (DPI) |

300 to 1200 |

|

Etchant Type |

Ferric chloride, nitric acid, hydrochloric acid |

|

Etchant Concentration |

Varies by metal and etchant |

|

Temperature |

20°C to 50°C |

|

Etching Time |

Few seconds to several minutes |

|

Laser Power |

10W to 100W |

|

Scan Speed |

Varies by laser system |

|

Pulse Frequency |

Varies by laser system |

|

Plasma Gas Type |

Argon, oxygen, chlorine |

|

Plasma Pressure |

1 to 100 mTorr |

|

Plasma Power |

100W to 1000W |

|

Etching Depth |

Few micrometers to several millimeters |

|

Tolerance |

±0.01 mm to ±0.1 mm |

|

Surface Finish |

Measured in micrometers (µm) |

There are many types of etched metal flat crafts, and the following are some common types:

1. Decorations

Metal painting: Creating various patterns and images on metal plates through etching techniques, commonly used for home decoration.

Wall decoration: Wall decoration made of etched metal plates, with a unique artistic effect.

2. Battery connector

Battery connector nickel sheet: Immerse the nickel sheet in an etching solution (such as an acidic solution) to corrode the exposed area and form the desired pattern and structure

3. Jewelry

Pendant: Etched metal pendant that can create intricate patterns and text.

Bracelet: Etched metal bracelet with various patterns and decorations on the surface.

4. Souvenirs

Medal: Etched metal medal, commonly used in sports events and commemorative activities.

Commemorative medal: Etched metal commemorative medal, customizable with various patterns and text.

5. Signage

Door number: Etched metal door number, durable and beautiful.

Signage: Etched metal signage, commonly used in public places and commercial buildings.

6. Stationery

Bookmark: Etched metal bookmark, exquisite and practical.

Business card holder: Etched metal business card holder, high-end and personalized.

7. Artworks

Sculpture: A sculpture made of etched metal plates, with a modern and artistic feel.

Printmaking: Etching metal prints can create complex patterns and details.

8. Customized gifts

Customized nameplate: Etched metal nameplate, customizable company logo, name, etc.

Customized gifts: such as etched metal keychains, badges, etc., with commemorative significance.

9. Industrial parts

Nameplate: Etched metal nameplate used to identify machines and equipment.

Scale dial: Etched metal scale dial, used for measuring instruments and meters.

These etched metal flat crafts not only have practical value, but also have high artistic and collectible value. Through different designs and techniques, various styles and uses of metal crafts can be produced.

Product Application

The application range of metal etching flat crafts is very wide. In the field of home decoration, it can be made into metal paintings, wall decorations, screens, trays, etc., adding artistic atmosphere to indoor spaces; In terms of gift customization, etched crafts can be made into commemorative medals, plaques, business card holders, bookmarks, etc., which are both practical and have commemorative significance; In the business field, etched metal signs, company nameplates, etc. are also widely used for corporate image display. In addition, metal etching crafts can also be used to make high-end jewelry and industrial parts, meeting diverse needs.

Be used in a wide range of industries.

Battery connection nickel sheet

Measuring instruments

business card

souvenir

Etching metal mesh sheet

Metal bookmarks

Company Profile

Zhuhai Senlong is a high-tech enterprise specializing in metal etching processing, committed to providing customers with high-quality and high-precision OEM metal etching solutions. We have advanced production equipment, a professional technical team, and a strict quality management system, which can meet the diverse needs of customers in the fields of electronics, communications, automotive, medical, aerospace, and more.

We specialize in the following metal etching processing services:

Precision metal etching: including etching treatment of materials such as stainless steel, copper, aluminum, titanium, nickel, etc., suitable for precision parts such as electronic components, battery connectors, sensors, filters, etc.

Customized design: Provide one-stop services from design, sampling to mass production according to customer needs, supporting complex patterns, micro holes, and high-precision size requirements.

Surface treatment: Provide post-treatment services such as polishing, electroplating, oxidation, and coating to improve the corrosion resistance, conductivity, and aesthetics of the product.

Strict quality control: From raw material procurement to finished product delivery, strict quality testing is implemented throughout the entire process to ensure that every product meets customer requirements.

We adhere to a customer-centric approach, providing customized services with quick response and efficient delivery. Whether it's small-scale sampling or large-scale production, we can meet customer needs with our professional team and flexible production capabilities.

We have established long-term cooperative relationships with many well-known domestic and foreign enterprises, and our products are exported to international markets such as Europe, the United States, Japan, and South Korea, winning widespread trust and praise from customers.

If you have any needs for metal etching processing, please feel free to contact us at any time! We will provide you with the most competitive solutions to help your product succeed.

During the exhibition, we signed cooperation agreements with [number] customers and established long-term strategic partnerships with [partner name], laying a solid foundation for future development.

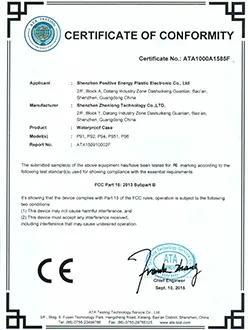

Certifications

We have obtained 8 technical patents and passed ISO9001:2015 IATF16949: The 2016 quality system certification, as well as ROHS \ CE \ FCC \ REACH \ SVHC and other testing certifications, ensure that our products and services comply with international quality management standards in design, production, delivery and other aspects. We provide you with stable and reliable high-quality products to meet your diverse needs.

The production process of etching flat handicrafts

1. Design and Preparation

Design patterns: Use CAD software or hand drawn design patterns.

Material selection: Common materials include metals such as copper and stainless steel

2. Material handling

Cleaning materials: Ensure that the surface is free of oil stains and impurities.

Coating with a corrosion-resistant layer: Coating the surface of the material with photoresist or wax as a corrosion-resistant agent.

3. Pattern transfer

Exposure: Transfer the design pattern onto the resist layer through a photomask, and UV exposure hardens some areas.

Development: Remove the uncured resist layer and expose the area to be etched.

4. Etching

Chemical etching: immersing the material in an etching solution (such as acid or alkali) to corrode the exposed area.

Physical etching: using laser or plasma for etching, suitable for high-precision requirements.

5. Cleaning and post-processing

Remove the corrosion-resistant layer: Use solvents or mechanical methods to remove the remaining corrosion-resistant layer.

Cleaning: Thoroughly clean the material to remove etching residues.

Surface treatment: Polishing, electroplating, or coating to enhance appearance and durability.

6. Quality inspection and packaging

Quality inspection: Check the size, pattern accuracy, and surface quality.

Packaging: Properly package to prevent damage during transportation.

Key equipment and materials

Equipment: exposure machine, etching machine, cleaning equipment, etc.

Materials: Corrosion inhibitor, etching solution, cleaning agent, etc.

precautions

Safety protection: Wear protective equipment during operation to avoid contact with harmful chemicals.

Environmental protection treatment: Properly handle waste liquids and gases to reduce environmental pollution.

Technical advantages

Advanced equipment: Introducing internationally leading etching production lines, laser cutting equipment, and testing instruments to ensure product accuracy and consistency.

Exquisite craftsmanship: Using various processes such as chemical etching and laser etching, it can process metal materials with thicknesses ranging from 0.01mm to 2mm, and the etching accuracy can reach ± 0.01mm.

Packaging and transportation

Our transportation advantages:

Global coverage: Cooperating with multiple international logistics companies, our service network covers over 200 countries and regions worldwide.

Multiple transportation modes: providing sea, air, railway, and multimodal transport to meet the needs of different customers.

Timeliness guarantee: Optimize transportation routes to ensure timely arrival of goods and support expedited transportation services.

Full tracking: providing real-time logistics information to keep you informed of the status of your goods at any time.

Customs clearance services: A professional team assists in handling export customs declaration, document preparation, and destination customs clearance to ensure smooth processes.

High standard packaging to protect every product you have

Our packaging features:

Customized design: Design the most suitable packaging solution based on product shape, size, and transportation requirements.

High quality materials: use waterproof, moisture-proof and anti-seismic packaging materials, such as wooden boxes, corrugated boxes, foam fillers, etc.

Multi layer protection: Adopting a multi-layer protective structure consisting of inner lining, buffer layer, and outer box, effectively resisting impacts and vibrations during transportation.

Clear labeling: The packaging is marked with fragile, moisture-proof, and upward labels on the outside to ensure proper handling during transportation.

Environmental protection concept: Prioritize the use of recyclable and biodegradable environmentally friendly materials, and practice the concept of green packaging.

FAQ

Q: What is the precision of metal etching?

A: Our metal etching process has an accuracy of ± 0.01mm, which can meet the processing needs of high-precision parts and is suitable for industries such as electronics, medical, aerospace, etc.

Q: What are your international transportation methods?

A: We provide sea, air, rail, and multimodal transportation services, selecting the most suitable mode of transportation based on customer needs and cargo characteristics.

Q: Are your packaging materials environmentally friendly?

A: Yes, we prioritize the use of recyclable and biodegradable environmentally friendly materials, while ensuring the protective performance of packaging and practicing the concept of green packaging.

Q: What electronic components can metal etching be used for?

A: Metal etching is widely used in the manufacturing of electronic components such as flexible circuit boards, shielding covers, lead frames, sensors, etc.

Q: Do you provide etching processing for automotive parts?

A: Yes, we provide high-precision etching services for the automotive industry, including battery connectors, sensors, fuel injection parts, and more.

Q: Do metal etching products comply with medical industry standards?

A: Our etching process and materials comply with medical industry standards and are suitable for surgical instruments, implantable devices, medical sensors, and other products.

Q: Can you handle high-precision parts in the aerospace field?

A: sure. We have advanced equipment and processes that can meet the strict requirements of high-precision and high reliability parts in the aerospace industry.

Q: Does it support small batch customized production?

A: Yes, we support the full process service from sampling to mass production, whether it is small batch customization or large-scale production, we can meet customer needs.

Q: Do you provide export customs clearance services?

A: Yes, we provide professional export customs declaration and destination clearance services to ensure smooth customs clearance and timely delivery of goods.

Q: How to ensure product quality?

A: We conduct full process quality testing from raw material procurement to finished product delivery, using advanced testing equipment and technology to ensure that every product meets customer requirements

Hot Tags: etching metal flat crafts, China etching metal flat crafts manufacturers, suppliers, factory, copper nickel sheet, Diy Lifepo4 Battery Box, decorative metal etching, , Ebike Battery Enclosure, metal etching

Send Inquiry