Etched Hollow Engraved Decoration

✦Product name: Etched wind chimes

✦Style: Love

✦Product type: Wind spinner

✦Place of Origin: China

✦Material : Metal

✦Type:Technique Carved

✦Occasion:All festivals

Etched hollow engraved decoration is a decorative item characterized by exquisite design and unique craftsmanship. It is made of a mixture of 316L stainless steel and titanium metal, with a cool gray tone and lightweight. Through high-precision laser and manual etching techniques, delicate patterns are carved on the metal surface, combined with hollow and engraved designs, allowing romantic light and shadow to be projected when light penetrates, creating a strong sense of layering. The design inspiration for this decoration comes from the classic heart-shaped element, which combines the contour of the heart with the hollow effect through fine etching technology, making it both decorative and lightweight to wear. In addition, these products also support customized services such as engraving, material selection, and matching to meet the personalized needs of consumers.

Products Description

|

Material: |

Aluminum,Copper,Stainless Steel |

|

Packaging method: |

1pcs/bubble bag, master carton as you request. |

|

Heat press temperature: |

180~200 ℃, 60~80 seconds, medium pressure. |

|

OEM,ODM: |

Customization service provided |

|

Logo: |

Customized logo accept |

|

Brand Name : |

Senloong |

|

MOQ: |

50pcs |

|

Delivery time: |

15~20 days according to order quantity |

|

Sample time: |

1~3 days. |

Application scenarios

●Private residences and courtyard landscapes

●Commercial Space and Brand Display

●Cultural venues and public art

●Public facilities and urban landscape

●Creative Gifts and Personal Customization

Company profile

Welcome to Zhuhai Senloong Electronics Co., Ltd.

Zhuhai Senloong Electronics Co., Ltd. was established in 2004. We are a manufacturer and exporter specializing in metal etching processing, producing and selling nickel sheets, aluminum plates, copper busbars, automotive parts, mobile phones, computer hardware structural components, speaker screens, various etching filters, hardware decorative etching products, widely used in fields such as semiconductor devices, electronic components, mold manufacturing, and mechanical processing. We can design according to your needs. Please feel free to provide us with pictures.

We are located in Guangdong Province, China, with convenient transportation. All of our products meet international quality standards and are highly appreciated in various markets around the world. If you are interested in any of our products or would like to discuss custom orders, please feel free to contact us at any time. We look forward to establishing successful business relationships with you around the world in the near future.

Exhibition and Collaboration

During the exhibition, we pay special attention to technical dialogue and demand matching with visitors. Through on-site demonstrations, one-on-one negotiations, and special forums, we gain a deep understanding of the demand characteristics and development trends of different markets. At the same time, we actively engage in strategic cooperation negotiations with upstream and downstream enterprises in the industrial chain, and have reached multiple cooperation intentions in areas such as technology collaboration, market expansion, and business model innovation.

company advantage

1.Industry experience and technological accumulation

The company has been focusing on the etching processing industry for 20 years, accumulating profound technical accumulation and rich production experience, and can provide customers with high-quality products and services. This long-term industry experience gives it significant advantages in etching processes, enabling it to meet diverse customer needs and provide customized solutions.

2.Well developed production facilities and equipment

The company has a production factory of over 11000 square meters, equipped with advanced automated production lines such as spraying and screen printing equipment, ensuring stable product quality and high production efficiency. In addition, the company also has imported precision equipment such as laser cutting machines, CNC machine tools, etc., further improving processing accuracy and efficiency.

3.Quality Management System and Certification

The company has passed the ISO9001:2015 quality management system certification, and strictly controls the quality from raw material procurement to finished product delivery to ensure stable product quality. At the same time, the company has implemented a strict quality control system, including IQC, IPQC, and OQC, to ensure that every process meets the standards.

4.Flexible process flow and fast response capability

The company can flexibly arrange the production process, optimize the production plan, and shorten the delivery time according to customer needs. With a mature production management system and rich production experience, the company is able to quickly coordinate resources, avoid production delays, and provide accurate delivery time estimates.

5.One stop service and customer support

The company provides comprehensive one-stop services, including full process support from design and research and development, production and processing, to after-sales service. The company also has a one-on-one professional customer service team that can quickly respond to customer needs, solve customer problems, and provide efficient service experiences.

6.Price competitiveness and cost advantage

Due to having its own factory and comprehensive supply chain management, the company is able to effectively control costs and offer highly competitive prices. At the same time, the company cooperates with multiple well-known domestic and foreign suppliers to ensure stable supply of raw materials and reasonable prices.

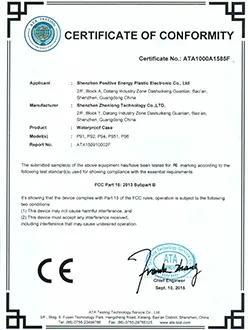

Patent certificate

We have 8 independently developed core technology patents covering key areas such as product design, production processes, and intelligent applications. We have passed ISO 9001:2015 quality management system certification and IATF 16949:2016 automotive industry quality management system certification, ensuring that the entire process from raw material procurement to production manufacturing and product testing meets the stringent requirements of the global high-end market.

IATF 16949:2016

ISO 9001:2015

ROHS Certificate

CE Certificate

SGS Certificate

FCC Certificate

Production process flow

1. Design and plate making

CAD modeling: Create 3D models using computer-aided design (CAD) software to ensure pattern symmetry and structural rationality.

Template production: Metal templates (such as stainless steel masks) are made using laser engraving or photochemical etching techniques for subsequent etching processes.

2. Material preparation

Metal sheet selection: Select materials such as aluminum, stainless steel, copper, etc. according to the needs, with a thickness usually ranging from 0.3 to 1.2mm.

Surface treatment: Polishing, cleaning to remove oil stains, ensuring etching uniformity.

3. Etching process (core steps)

(1) Photochemical Etching

Coating photoresist film: Covering the metal surface with photosensitive adhesive and hardening the pattern part through UV exposure.

Development: The unexposed portion is dissolved by a chemical solvent, exposing the area that needs to be etched.

Etching solution immersion: using acidic solutions (such as nitric acid, ferric chloride) to corrode metals, forming a hollow effect.

Gel cleaning: Remove the remaining photoresist film to obtain a preliminary hollow structure.

(2) Laser Etching

Applicable materials: high hardness metals (such as stainless steel, titanium alloy).

Technical advantage: The accuracy can reach 0.01mm, suitable for complex patterns.

4. Precision machining and hollow processing

Hand carved trimming: Fine tune the edge burrs.

Stereoscopic hollowing: Achieving 3D effects through multi-layer etching or CNC engraving.

Efficient and safe international package and transportation

1. Global transportation services

✚Covering over 200 countries and regions: collaborating with international logistics giants such as DHL, FedEx, and UPS to seamlessly connect with the global market.

✚Flexible choices for multimodal transport: sea freight (cost optimization), air freight (urgent orders), railway (Eurasian land transport), multimodal transport (complex routes).

2. Timeliness and reliability

✚Fast track service: Supports 3-5 day expedited air freight (applicable to high-value orders).

✚Intelligent route optimization: selecting the optimal path through big data analysis to reduce transit delays.

3. We offer the following customized packaging:

✚Wrapped with EVA foam or bubble film to absorb the impact during transportation.

✚The outer layer of the box is made of thickened corrugated cardboard boxes or wooden boxes (high-value orders), which are resistant to pressure and moisture.

✚The packaging is labeled with fragile, moisture-proof, and upward labels on the outside to ensure proper handling during transportation.

✚Air transportation shockproof packaging, adding anti-static bags and desiccants to cope with changes in air pressure and humidity.

✚Use FSC certified cardboard boxes and corn based biodegradable fillers.

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a factory established in 2004.

Q: What is the ordering process?

A: 1. Please tell us the product you want to order, including the quantity

2. We will calculate the total amount for you

3. After you approve the total amount and product details, we will issue an invoice for you

4. Payment will be made after everything is normal

5. We arrange shipment and provide you with a tracking number.

Q: What is the material of your product?

A: This material is metal. Other materials are available for customization.

Q: How does your factory conduct quality control?

A: In terms of quality management, quality control teams are composed of quality management personnel with professional knowledge and practical experience. Each product has undergone thorough testing before being released from the warehouse.

Q: Can I obtain samples before mass production?

A: of course! We will produce pre production samples for you to evaluate the quality. We will start production after you confirm this sample.

Q: What is your payment method?

A: We accept PayPal, wire transfer, credit card, and trade guarantee orders

Q: Can I get a discount if I place an order?

A: Yes. We have different price ranges based on different order quantities and product materials.

Q: I received it, but it was wrong. What should I do?

A: 1: If you provide incorrect information and confirm the wrong artwork or production plan, we apologize and you will bear the cost of remaking.

2: If our product does not match our artwork or production plan, we will refund you or send you a replacement.

Only in this way can we establish a strong relationship with every customer, making their loyalty and our customer retention rate higher compared to our competitors.

Hot Tags: etched hollow engraved decoration, China etched hollow engraved decoration manufacturers, suppliers, factory, Nickel Strip for 18650 Lithium Battery, Speaker Cover Metal Mesh, Metal 12V Battery Box, conductive metal etching, Battery Copper nickel Sheet, Conical Filter Stainless Steel Mesh

Send Inquiry