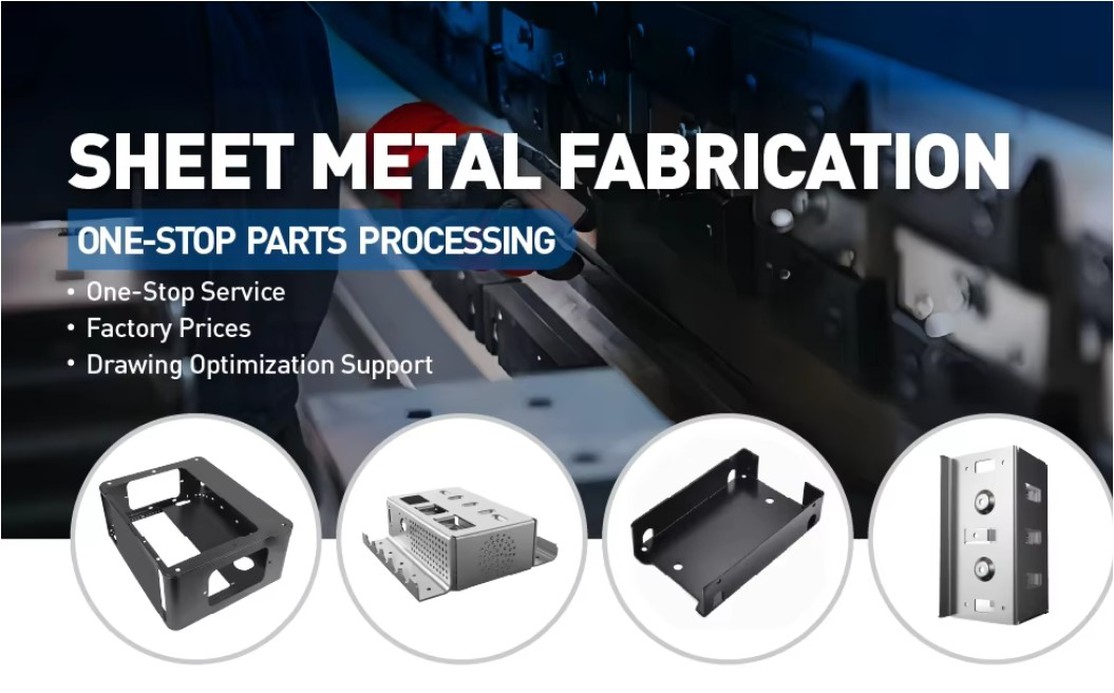

Metal Enclosure Box For Electronic

■ Product Type: Empty Metal Enclosure

■ Material: Stainless Steel/Aluminum/Brass

■ Surface treatment: paint/powder coating/electroplating/polishing

■ Color: Customized color

■ Size: Customized Size

■ Minimum order quantity: Low minimum order quantity is acceptable

■ Application: Commercial/Industrial/Outdoor

■ Logo: silk screen printing, laser marking

SenLoong is a professional company that produces customized metal parts, including CNC machined parts, automatic lathe parts, rivets, silver contacts, and metal stamping parts.

Since 2008, we have been focusing on this industry and can provide customers with one-stop services. Assist in designing, producing drawings, making samples, mass production, inspection, assembly, packaging, and transportation.

We believe that Senlong will become a trusted partner for your company. Senlong is willing to work hand in hand with you to achieve common development and create a better future together.

Professional team

Our company currently has over 200 employees, including more than 50 senior technical personnel.

Customization service

Supports OEM/ODM, customizable capacity, shell size, and brand identification.

|

Project |

Specifications |

| Material | Stainless Steel/Aluminum/Brass |

| Surface treatment | Paint/powder coating/electroplating/polishing |

| Battery box size | Customized |

| Delivery time | 1-25 days after the order, prepayment based on product structure and quantity |

| Quotation | Based on your drawings (2D or 3D engineer drawings) |

| Surface treatment | Powder coating and spray painting |

| Regular colors | White, gray white, black (any color can be customized) |

| Certification | CE/RoHS/UN38.3/MSDS |

Product introduction

product description

This metal shell is made of high-quality metal materials such as cold-rolled steel plates and aluminum alloys. It is processed and formed through precision stamping, bending, and welding processes, and its structural strength far exceeds that of plastic shells. As a professional protective carrier, electronic metal casing boxes have become the "safety guards" of precision electronic equipment in industrial control, communication transmission, instrumentation, new energy and other fields. They have excellent structural strength, multiple protective performance and flexible adaptability, ensuring stable operation of equipment.

Different shapes can be customized

We offer a wide range of customization options to meet the diverse needs of different customers.

In terms of materials, in addition to the standard SPCC material, customers can choose more corrosion-resistant stainless steel or lighter aluminum alloy according to their needs.

In terms of size customization, we can flexibly adjust the length, width, and height of the product within a certain range of error.

High quality metal substrate

Cold rolled steel plate version: The surface is treated with electrostatic spraying and phosphating, which has excellent scratch resistance and rust resistance. The salt spray test at room temperature can reach more than 48 hours, and it can resist harsh environmental erosion such as oil pollution and humidity in industrial workshops;

Aluminum alloy version: The weight is reduced by 30% compared to the same specification steel plate box, combining lightweight and high strength, and comes with excellent thermal conductivity to assist in equipment heat dissipation, especially suitable for outdoor mobile electronic devices or weight sensitive scenarios.

Product application areas

➤ Industrial automation: used to protect PLC controllers, frequency converters, sensors, resist workshop dust, oil pollution, vibration, and electromagnetic interference, ensuring stable operation of production lines.

➤ Communication and Network: Suitable for outdoor base station signal receivers, fiber optic transceivers, network switches and other equipment to ensure stable transmission of communication signals.

➤ Instrumentation: Provides protection for laboratory testing instruments and on-site measuring instruments to prevent external environmental influences on the accuracy of precision instruments.

➤ In the field of new energy, it is used for equipment such as photovoltaic inverters, energy storage systems, and charging pile control modules. It has high temperature resistance and corrosion resistance, and is suitable for complex environments in outdoor or new energy power plants.

Production process

Step 1: Material cutting

Laser cutting is one of the most common cutting methods in sheet metal processing. Based on the size specifications of the finished sheet metal parts, metal stainless steel and other sheets are laser cut into the required size for future use. This process is collectively referred to as cutting.

01

Step 2: Bending

Bending is the process of CNC bending the cut material according to the size specifications of the sheet metal workpiece, and how to prepare it for the next stage of sheet metal welding.

02

Step 3: Welding

Welding can be divided into two methods: manual welding or robot automatic welding. It is a process of welding the cut material into finished sheet metal parts according to the processed finished sheet metal parts.

03

Step 4: Surface Treatment

There are also many surface treatment processes, including hot-dip galvanizing, cold dip galvanizing, galvanizing coloring, powder coating, sandblasting, anodizing coloring, blackening, polishing, and brushing.

04

our Certifications

In addition to ISO certification, we have also obtained numerous industry-specific certifications and honors, including ROHS, CE, FCC, REACH, SVHC, and other testing certifications. We welcome you to contact us to view more of our certificates.

brand trusted choice

Our company collaborates with Samsung Electronics, Amphenol, Philips, Guxin, Huawei, Sony, BYD LG,COSMX,AZURE,Greenway, We have collaborated with well-known brands such as Walt Disney and established long-term partnerships with them.

Product packaging and transportation

- To better ensure the safety of your products, we will provide professional, environmentally friendly, convenient, and efficient packaging services.

- DHL/UPS/FedEx/TNT, Door to door service.

- Air or sea freight, full container load; Airport/Port Reception Desk.

- We can also meet your requirements.

FAQ

FAQ

01.Can the outer casing protect the equipment from vibration and impact during transportation or handling?

The corners are reinforced with rounded transitions or reinforcing ribs to reduce stress concentration during external impact;

The bottom can be optionally equipped with anti slip shock-absorbing foot pads, which can cushion the bumpy vibrations during transportation and prevent internal components (such as wiring terminals and sensors) from loosening or being damaged due to vibration.

02.Is the internal structure of the casing flexible?

Reserve multiple sets of standard installation holes, support the installation of brackets, rails, or partitions, and divide space according to equipment size to accommodate the orderly placement of components such as circuit boards, power modules, and wiring terminals;

03.Can it adapt to electronic devices of different sizes?

Hot Tags: metal enclosure box for electronic, China metal enclosure box for electronic manufacturers, suppliers, factory

Send Inquiry