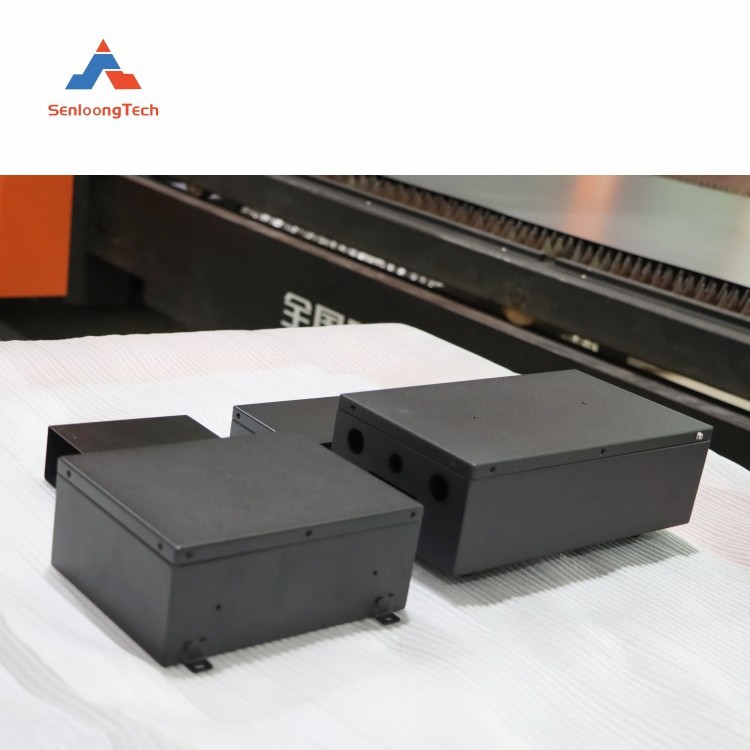

12v 5ah Battery Storage Box

✦Material: Matal

✦Logo:Custom Logo

✦Output Power: 12V

✦Battery Type:Cylindrical

✦Product Name:Diy Empty battery box

✦Used for:Emergency power supply, solar storage system, renewable energy projects, and customized energy

✦MOQ: 5 pcs

This 12V 5AH battery storage box has a nominal voltage of 12V, a capacity of 5AH, and a weight of approximately 1.42kg. The outer shell of the energy storage box is usually made of metal material, which has flame retardant, earthquake resistant, and corrosion-resistant characteristics. It is also suitable for wall mounted installation and widely used as a backup power source for solar energy storage and communication base stations. It is recommended to store it in a dry, clean, and well ventilated warehouse. It should be noted that if the small hole is blocked due to improper maintenance, the outer shell of the battery may deform due to high air pressure inside the battery. In summary, the 12V 5Ah battery storage box is a lead-acid battery with stable performance and wide applicability, suitable for various industrial and civilian scenarios.

Products Description

|

OEM: |

Available |

|

Color: |

Black,white or customed |

|

Battery Size: |

18650,21700,32650 |

|

Model Number: |

12V Battery Case |

|

Certification: |

ISO9001 |

|

Features: |

IP54 |

|

Packing: |

Natural Cartons |

|

Machinery Test: |

Report Provided |

|

Application: |

EV,E-bike,Agriculture,Solar System |

|

Feature: |

DIY Assemble |

Common applications

◉ Emergency power supply: used for UPS uninterruptible power supply, fire-fighting equipment, emergency lighting systems and other equipment.

◉ Energy storage system: solar energy storage, backup power supply for communication base stations.

◉ Mobile devices: portable scenarios such as power tools, medical equipment, security monitoring, etc.

Company introduction

Zhuhai Senloong Electronics Co., Ltd. is a professional manufacturer and service provider of precision electronic components, sheet metal boxes, battery box casings, and battery connectors for customers. It has two factories, namely a stamping factory and an etching factory. The enterprise has passed the ISO-9001 quality system and multiple product quality certifications. The company is in line with international standards in product development and advanced technology, continuously improving its management level and providing customers with high-quality and cost-effective metal accessory products. We have a highly creative new energy research and development team with a long background and rich production experience. Our designed and provided product series include various customized battery boxes, sheet metal brackets and frames, nickel sheets, copper sheets, aluminum bars, flexible connectors, metal filters, coffee machine accessories, customized parts and personalized sheet metal components, and hardware etching products .....

We have gathered a group of talents with profound professional knowledge and rich practical experience in various positions. Whether it is research and development innovation, production and manufacturing, marketing, or customer service, they can all demonstrate excellent professional standards.

We actively establish long-term stable cooperative relationships with our partners, adhere to the principle of mutual benefit and win-win, and jointly explore the market, share resources, and share risks. At the same time, we also extensively attract outstanding talents and advanced technologies from all sectors of society, constantly enriching and strengthening our strength.

Complete Certification System: IEC/UN38.3/CE/ROHS/Test Report/IOS9001/MSDS/SVHC

Why choose us

● Comprehensive customization services: covering a complete customization process such as requirement communication, scheme design, sample production, and mass production. The processing plant will also arrange production plans reasonably to ensure timely delivery of high-quality products.

● Multi dimensional service capabilities: We provide laser cutting, bending, welding, CNC machining services, as well as surface treatments such as anodizing, powder coating, nickel plating, etc. For parts without drawings, we can produce them according to customer requirements.

● Pay attention to the sample process: We understand that samples are the key to customized services, and usually process them first. After completion, we show the sample pictures to the customer, who decides whether to make payment or not.

● Experienced in international business: Our business collaborates with international clients and has experience in handling international trade, including language communication, transportation arrangements, and more.

● Comprehensive after-sales support: accepting various delivery terms, such as FOB, CFR, CIF, etc; Accept multiple payment currencies, such as US dollars, euros, Canadian dollars, etc; We accept multiple payment methods, such as wire transfer, letter of credit, and AliExpress; Oral communication supports English, Chinese, Japanese, etc.

Process flow of sheet metal box processing

1. Cutting: There are various ways of cutting, mainly including the following methods:Cutting machine,Punch press,CNC cutting,Sawing machine.

2. Fitter: countersunking, tapping, reaming, drilling

The countersunk angle is generally 120 ℃, used for pulling rivets, and 90 ℃ is used for countersunk screws and tapping British bottom holes.

3. Flanging: also known as hole drawing or flipping, it is to draw a slightly larger hole on a smaller base hole and then tap it, mainly using thin sheet metal processing.

4. Punch press: It is a processing process that uses molds to form. Generally, punch presses are used for punching, chamfering, material dropping, punching convex bulges (convex points), punching tearing, hole drawing, forming, and other processing methods.

5 Connection processes: welding, riveting, and threaded connection. Welding includes argon arc welding, spot welding, CO2 shielded welding, etc.

6. Surface treatment: such as polishing, spraying, electroplating, anodizing, etc. Spraying may include powder coating and spray painting, electroplating for rust prevention, and anodizing for aluminum materials.

Packing and Delivery

1, Packaging specification requirements

❖ The inner box of the battery casing is filled with cushioning materials such as bubble wrap and EPE pearl cotton. The outer box should be sturdy and have no gaps, and there should be no sound when shaking.

❖ The outer box must be a hard new cardboard box with at least one blank surface indicating the UN number, battery box model, voltage, and capacity.

2, Transportation scheme selection

❖ International express delivery (DHL/UPS/FedEx)

❖ Ocean freight plan

❖ Air freight plan

We will flexibly adjust the specific operation based on product type, transportation mode, and destination regulations.

FAQ

Hot Tags: 12v 5ah battery storage box, China 12v 5ah battery storage box manufacturers, suppliers, factory, 12V 18650 Battery Case, , 12v Lithium Battery Storage Box, Metal 12V Battery Box, 12v battery box, Empty 12v Battery Case

Send Inquiry