Spot Welded Pure Nickel Sheet

▲ Material: Pure nickel

▲ Product Name: Pure nickel sheet for batteries

▲ Application: Battery Pack Connection

▲ Thickness: 0.5mm-5mm

▲ Length: Customized

▲ OEM: Providing Services

▲ Quality control: 100% strict inspection

▲ Features: Customized design

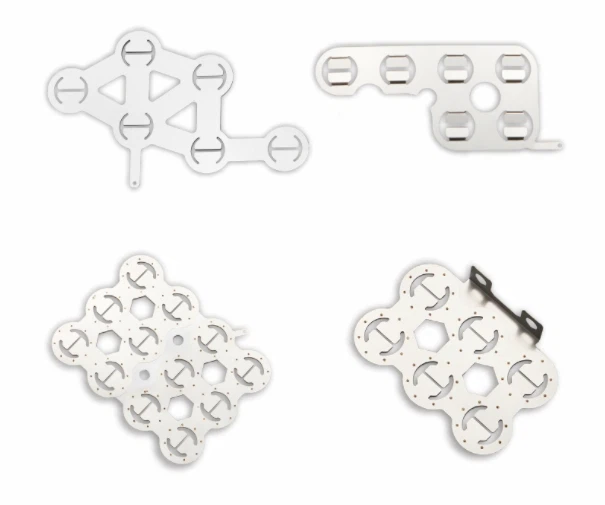

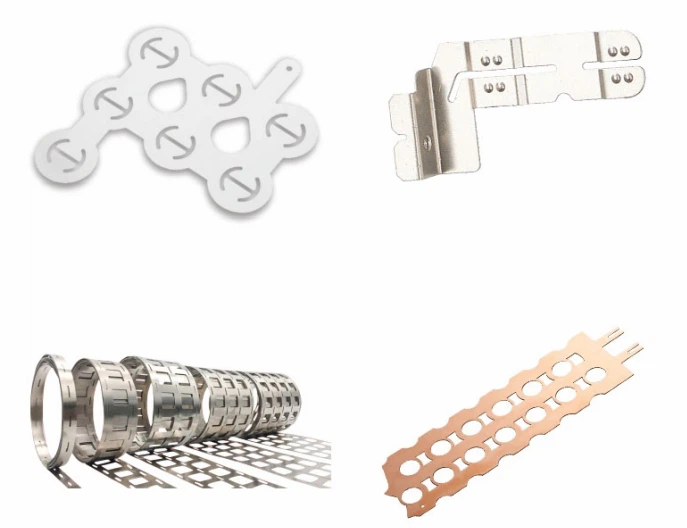

Spot welded pure nickel plate is a nickel metal sheet specially designed for resistance spot welding process, with high purity, excellent conductivity and corrosion resistance. Its spot welding performance is characterized by high tensile tension, easy operation, low resistivity (can pass current of 50A or above), good tin spot welding effect, and is suitable for scenarios such as power battery pack combination. Easy to press and shape, can be processed into sheet or strip shapes of different thicknesses (commonly 0.1~3.0mm). High quality solder joints, high joint strength after welding, and no issues such as virtual soldering or cracks. If further technical parameters or welding guidance are needed, specific application scenarios can be provided to obtain customized solutions.

Products Description

|

Type: |

Battery Solder, Battery Nickel, Nickel |

|

Keywords: |

nickel plate, battery, pure nickel sheet |

|

Features: |

Easy to process, can be processed using ordinary spot welding machines or laser welding machines. |

|

Method: |

Metal stamping/cutting/punching/bending/welding/deep drawing; |

|

Size: |

According to customer size |

|

OEM: |

Providing OEM services |

|

Minimum order quantity: |

Low minimum order quantity |

|

Product features: |

Good conductivity and corrosion resistance |

|

Certification: |

Compliant with RoHS environmental standards |

|

Size, shape, and thickness: |

Can be customized according to requirements |

Products application

Used for manufacturing connection plates, lugs, lead out plates, current cutoff plates, etc. for nickel hydrogen batteries, lithium batteries, combination batteries, and power batteries, suitable for electronic devices such as power tools, communication equipment, cordless power tools, electric bicycles, and video recorders.

company profile

Zhuhai Senlong Electronics Co., Ltd. is a professional manufacturer of battery connectors, nickel sheets, nickel bars, copper nickel composite plates, battery box casings, metal filters, and various precision metal stamping parts, with a history of more than 20 years. Our main products include the design, development, and production of high-speed stamping, precision connector terminals, iron shells, spring plates, and precision hardware molds. We are a reliable supplier in the battery management system industry, with a warranty period of 1 year. We firmly believe that we will not stagnate on the path of innovation. We continuously aim to meet market demand with reliable quality requirements, develop and produce green products with exquisite appearance, excellent performance, energy saving and environmental protection, and are committed to becoming a market leader. We welcome new and old customers from all walks of life to contact us to establish future business relationships and achieve success together.

company exhibition

our certificate and partner

Real time filming of the production process

The production process of pure nickel sheets directly affects their conductivity, welding performance, and long-term reliability in battery packs. The following is a brief description of the key process flow:

1. Raw material selection

2. Cutting Processing

3. Stamping forming (optional)

4. Welding process

5. Quality Inspection

6. surface protection

production equipment produce

package and transport

Packaging

We use various packaging methods based on the characteristics of the product and customer needs, including bubble wrap, pearl cotton, wooden boxes, cardboard boxes, etc., to ensure that the product is not damaged during transportation. The packaging will indicate product name, specifications, quantity, batch number and other information for customer identification and management.

Transportation

We offer multiple modes of transportation, including sea freight, air freight, railway transportation, and express delivery services. We choose the most suitable transportation method based on customer needs and the characteristics of the goods to ensure safe and fast delivery to the destination.

A comprehensive logistics management system is equipped during transportation, including cargo tracking, inventory management, order processing, and other services, to ensure timely and accurate management and monitoring of goods throughout the entire transportation process.

our High quality after-sales service

- Provide 24-hour online service to ensure timely support for customers during the after-sales process.

- Provide free technical consultation to help customers solve problems during product use.

- Provide detailed product manuals and operation instructions to ensure long-term customer experience.

- Quick response mechanism, after-sales team provides solutions within 12 hours to ensure customers have no worries.

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a factory, so we can provide you with competitive prices.

Q: Do you accept OEM/ODM?

A: Yes, we have a professional OEM design team.

Q: Can I provide you with samples or drawings as a production basis?

A: Of course, we support drawings in formats such as CAD/PDF/SOLIDWORKS.

Q: If the item I received is different from the picture, what do I do?

A: The picture only show some of our samples, so please confirm the order with a picture before ordering. If you are still not satisfied, please contact us.

Q: What should we do if we don't have the drawings?

A: Please send sample images or drafts with dimensions.

Hot Tags: spot welded pure nickel sheet, China spot welded pure nickel sheet manufacturers, suppliers, factory, Battery Nickel Sheet, nickel sheet, Nickel Soldering Tabs for Battery, , Polygonal Battery Nickel Sheet, pure nickel sheet

Send Inquiry