Battery Connector Copper Nickel Sheet

■ Product Name: Battery connector copper nickel sheet

■ Material: Copper+Nickel, Copper

■ Size: Customized

■ Used for: 18650 32650 battery pack

■ Model: OEM

■ Model: Battery Aluminum Copper Nickel Plate

■ Origin: Guangdong, China

The copper nickel sheet of battery connectors produced by our factory is a metal sheet used to connect the positive and negative poles of batteries and achieve current transmission. It plays a crucial role in the battery pack, ensuring stable and reliable connections between batteries, enabling the battery pack to function properly and provide power to devices. The requirements for connecting pieces vary in different application scenarios. In energy storage lithium battery modules, connecting plates ensure reliable connections between batteries to achieve stable energy output.

It is a customized product, and we can strictly design, produce, and supply different types of battery boxes according to the technical requirements of users.

product parameters

|

Product Name:

|

Battery connector copper nickel sheet

|

|

Features: |

Customized design |

|

Materials:

|

Pure nickel, copper nickel, nickel plating, etc

|

|

Size:

|

Customer Scale

|

|

Applications:

|

Industrial, furniture, automotive, motorcycle, etc.

|

|

Characteristic:

|

Durable

|

|

Method:

|

Metal stamping, cutting/punching/bending/welding/deep drawing;

|

|

Minimum order quantity:

|

Low minimum order quantity is acceptable

|

|

Sample:

|

Support sample

|

|

Surface treatment:

|

highly polished |

Application fields of battery connectors

New energy vehicles: used to connect various battery cells in the power battery pack

Energy storage system: used in energy storage battery modules to connect battery cells

Portable electronic devices: such as mobile phones, laptops, power banks, etc

Our advantages

We are a factory with experience in OEM and ODM services. Customer first, affordable prices.

With rich production experience, we can accurately estimate the delivery time for you.

Continuous innovation and research and development to meet the ever-changing demands of the market.

We use advanced production equipment and technology to ensure efficient production and high-quality output of our products.

Organize technical training to enhance the team's professional skills and provide customers with better quality services.

Having a comprehensive supply chain management system to ensure the stability and timeliness of material supply.

Senloong's workshop

Our workshop is equipped with various professional equipment such as zinc alloy die-casting machines, presses, punch presses, polishing machines, laser cutting machines, CNC bending machines, rolling machines, argon arc welding machines, spot welding machines, and coordinate measuring machines, which can complete a series of processes from mold making to finished product polishing.

Products Description

1. Material preparation

Copper layer: T2 copper with high conductivity is usually selected, and the thickness can be customized according to the needs.

Nickel layer: Pure nickel strip or electroplated nickel layer is used, usually with a thickness of copper layer, and then a nickel layer is electroplated on the copper substrate.

2. Stamping forming

Mold design: Design precision progressive molds based on the shape of the connecting piece (such as square, circular, or irregular).

Stamping process: High speed punching machine for continuous cutting, completing the shape and hole processing in one step.

3. Surface treatment

--- 4. Heat treatment (optional) ---- 5. Quality inspection ----- 6. Packaging and Storage

zhuahai senloong electronics Co.,ltd

some statistics about us you must know

Choose the plan that suits you best.

20

+

Years of experience

36

%

TECHNICIANS & WORKERS

578

+

SATISFIED CUSTOMERS

184

+

completed projects

our exhibition

We sincerely look forward to meeting you at the next exhibition. Whether you are an industry practitioner, potential customer, or a friend interested in metal products, you are welcome to visit our booth to discuss industry development trends and experience our high-quality products and services together. Your arrival will be our greatest honor, and we look forward to working together with you to create a better future!

partners and certificate

brand trusted choice

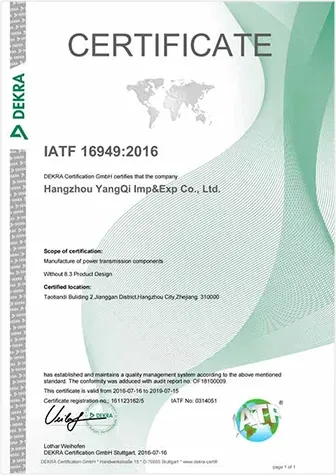

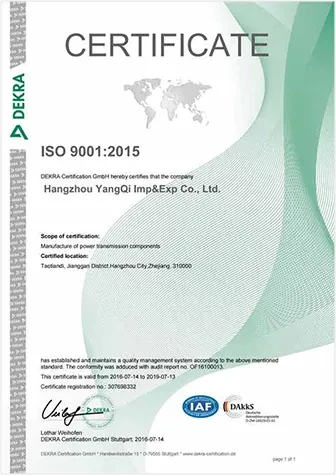

Our Certificate

IATF 16949:2016

ISO 9001:2015

Environmental Management System Certificate

oEM customizatiom process

package and transport

► Customized packaging

Provide customized packaging solutions based on customer needs to ensure optimal protection of products during transportation, while optimizing costs and efficiency.

► Shipping method

1. FedEx/DHL/UPS/TNT samples, door-to-door.

2. Bulk cargo air or sea freight.

3. Designated freight forwarders or customers who can negotiate transportation methods.

FAQ

Hot Tags: battery connector copper nickel sheet, China battery connector copper nickel sheet manufacturers, suppliers, factory, 18650 Copper Nickel Sheet, Battery Copper nickel Sheet, , copper nickel sheet, High Power 32650 Copper Nickel Sheet, Welding Battery Pack Copper Nickel Sheet

Send Inquiry