What is the shear strength of a pure nickel sheet?

Jun 30, 2025

Hey there! As a supplier of pure nickel sheets, I often get asked about the shear strength of these sheets. So, I thought I'd write this blog to share what I know and hopefully clear up any confusion you might have.

First off, let's talk about what shear strength actually means. Shear strength is the ability of a material to resist forces that cause its internal structure to slide against itself. In simpler terms, it's how well a material can handle being cut or sliced. When it comes to pure nickel sheets, shear strength is a crucial property, especially in applications where the sheets might be subjected to cutting, stamping, or other processes that involve shearing forces.

Pure nickel is a highly malleable and ductile metal. Its unique atomic structure gives it some pretty impressive mechanical properties. The shear strength of a pure nickel sheet can vary depending on a few factors. One of the main factors is the thickness of the sheet. Generally speaking, thicker sheets tend to have higher shear strength. This is because there's more material to resist the shearing forces. For example, a 1mm thick pure nickel sheet will have a different shear strength compared to a 0.5mm thick one.

Another factor that affects shear strength is the purity of the nickel. As a supplier, I make sure that our pure nickel sheets have a high level of purity. The purer the nickel, the more consistent its properties, including shear strength. Impurities can act as weak points in the material, reducing its ability to resist shear forces. So, when you're looking for a pure nickel sheet with good shear strength, it's important to choose a high - purity product.

The manufacturing process also plays a role. Sheets that are cold - rolled often have better mechanical properties, including shear strength, compared to those that are hot - rolled. Cold rolling involves passing the sheet through rollers at room temperature, which can align the metal's grains and increase its strength.

Now, let's get into some numbers. The shear strength of pure nickel sheets can range from around 120 MPa to 250 MPa, depending on the factors I mentioned earlier. But these are just general estimates. To get a more accurate value for a specific sheet, you might need to do some testing. There are various testing methods available, such as the punch - shear test or the double - shear test. These tests involve applying a shearing force to the sheet and measuring the point at which the material fails.

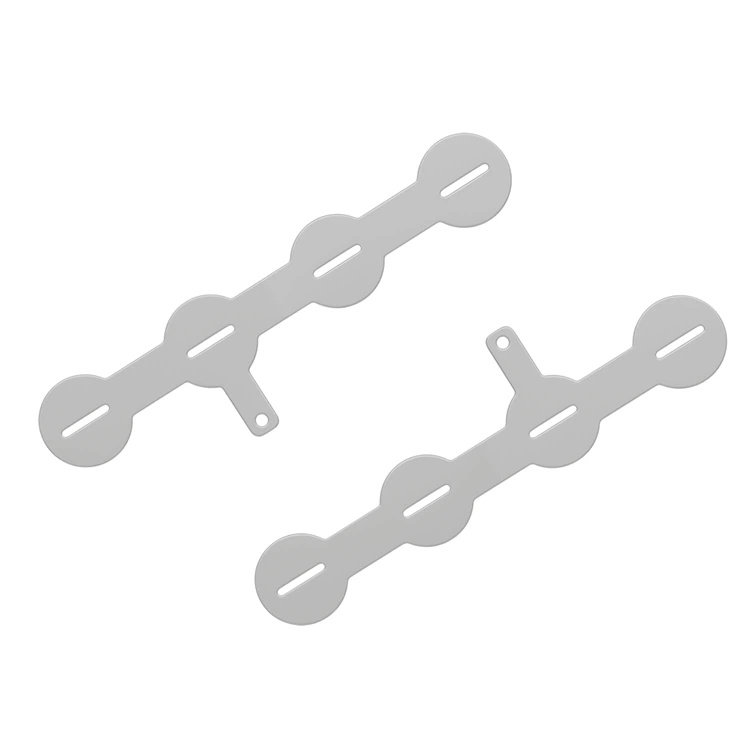

In practical applications, the shear strength of pure nickel sheets is very important. For example, in the battery industry, pure nickel sheets are widely used. Check out our 18650 Nickel Sheet For Battery and 18650 Connector Nickel Tabs. These products need to have good shear strength because they might be cut or shaped during the manufacturing process. If the shear strength is too low, the sheets could tear or deform easily, which would affect the performance and reliability of the batteries.

Another application is in the electronics industry. Pure nickel sheets are used in the production of various components. The Triangle Shape Battery Nickel Tabs are a great example. They need to be able to withstand the shearing forces during the assembly process. If they can't, it could lead to poor connections and malfunctioning of the electronic devices.

So, if you're in the market for pure nickel sheets and you're concerned about shear strength, you've come to the right place. As a supplier, I've got a wide range of pure nickel sheets with different thicknesses and purities. I can help you choose the right product based on your specific requirements. Whether you need sheets for the battery industry, electronics, or any other application, I've got you covered.

If you're interested in learning more or want to start a purchase negotiation, don't hesitate to reach out. I'm always here to answer your questions and provide you with the best solutions for your needs.

References

- Callister, W. D., & Rethwisch, D. G. (2010). Materials Science and Engineering: An Introduction. Wiley.

- ASM Handbook Volume 1: Properties and Selection: Irons, Steels, and High - Performance Alloys. ASM International.