36v 18ah Ebike Battery Case

✤ Output power: 5 kWh, 2 kWh

✤ Brand Name: Senloong

✤ Model: OEM Battery Box

✤ Features: Durable

✤ Size (length * width * height): Customized

✤ Weight: Customized

✤ Material: Metal

The 12V lithium car battery box is a power solution designed specifically for automobiles, with a nominal voltage of 36V and a rated capacity of 18Ah. It has a lighter weight, higher energy density, and better performance, providing stable and reliable power support for car starting and on-board electrical equipment. The shell is mainly made of aluminum alloy or high-strength composite materials, which balance lightweight and protection, and have good impact resistance. It meets the IP67 waterproof and dustproof standards and is mainly used for electric bicycles, electric scooters, and scooters, supporting personalized needs such as waterproof level improvement, size customization, anti-theft lock design, etc.

Product characteristics

The regular products that we already produce.

High energy density

The 12V lithium car battery box can store more electricity, providing a more durable power supply for vehicles and meeting the needs of various electrical equipment in cars.

Lightweight design

The weight is significantly reduced compared to lead-acid batteries of the same specification, which helps to reduce the overall weight of the vehicle, improve fuel economy or range.

Long service life

Having a longer cycle life, it can generally reach thousands of charge and discharge cycles, reducing replacement costs and hassle compared to lead-acid batteries.

Fast charging and discharging

Capable of supporting fast charging, it can be fully charged in a short period of time, reducing user waiting time. At the same time, ensure stable output and ensure the normal operation of car start-up and electrical equipment.

After-sales warranty service

All our products have warranty service,the motor warranty ten years,other accessories warranty two years,any problem we will try to solve for you!

Wide working temperature range

Can adapt to harsh environments, has high safety performance, equipped with multiple protective measures to prevent damage and safety accidents.

Industrial application

Peak regulation and valley filling: balance power grid load and reduce electricity cost.

Microgrid: Provide an independent power system for industrial parks.

Electric forklift truck / AGV: to provide power for industrial vehicles.

Be used in a wide range of industries.

Electric Boat

Communication base station

RV

OEM Service Process

The key steps of customized services

01

Requirement confirmation

Provide detailed specifications such as dimensional drawings/functional requirements/hole positions/surface treatments, etc., and submit physical or design drawings of internal components.

02

Design and quotation

Manufacturers evaluate requirements and design prototypes.

After the customer confirms the plan, the contract will be signed, and a 40% deposit is required for some parts.

03

Quality Control

Material selection, such as stainless steel/aluminum alloy , precision machining, stamping/laser cutting/bending, etc. → assembly and debugging, checking dimensions and assembly accuracy.

04

Delivery

customer requirements, shipped after final payment.Extra review of supplier qualifications and full process supervision for special scenarios.

Process flow and production workshop

Production process

The basic steps of sheet metal processing include design, cutting, forming, welding, surface treatment, and other processes.

Firstly, during the design phase, sheet metal boxes usually have drawings that are unfolded into a plan view, and materials such as stainless steel, cold-rolled steel plates, aluminum plates, etc. are selected.

Next is cutting, which means cutting the material. Choose the appropriate cutting method according to different needs, including laser cutting, plasma cutting, shearing machine or punching machine.

Then there is molding, including bending, stamping, and rounding. Bending requires the use of a bending machine, and the bending coefficient needs to be calculated. Here, we need to mention the selection of the mold.

The next step is the connection process, which includes welding, riveting, and threaded connections. Riveting may be used in areas where welding is not possible, such as connecting different materials. Threaded connections are screws and nuts that are easy to disassemble.

Next is surface treatment, including powder coating and spray painting, electroplating for rust prevention, and anodizing for aluminum materials.

Inspection is also a key step, which depends on dimensions, sealing, strength, etc.

Finally, there is packaging to protect the surface, prevent scratches and moisture.

COMPANY PROFILE

CCC

in one-stop service

Zhuhai Senlong Co., Ltd. has always been at a market height of continuous improvement and innovation in the same industry. For many years, it has been committed to developing product standards with innovative value concepts and has maintained a good commercial reputation in energy in Guangdong Province and other regions. Our product line includes battery boxes, metal boxes, sheet metal shells, battery connectors, battery nickel sheets, copper sheets, soft connectors, etc., and has passed multiple national tests and certifications. We provide professional OEM/ODM services to provide you with the most competitive products and services. Welcome to visit our factory for inspection.

We actively participate in various industry exhibitions, showcasing the outstanding charm of sheet metal shells for distribution boxes in all aspects. Our distribution box sheet metal shell has attracted the attention of many visitors with its exquisite craftsmanship, reliable quality, and innovative design. Every time we participate in the exhibition, our booth is carefully designed with unique layout and modern display methods, perfectly presenting the characteristics and advantages of our products. We also established closer connections with customers at the exhibition, laying a solid foundation for the sustainable development of our business

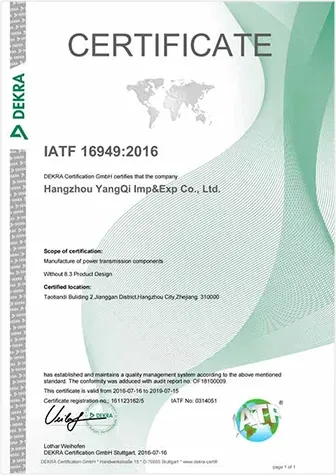

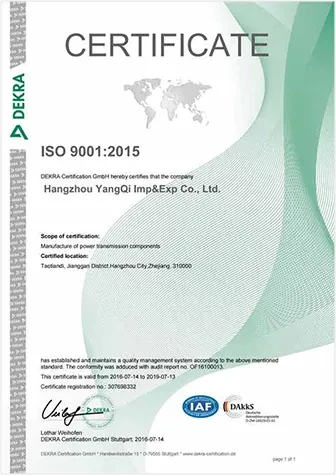

Our Certificate

IATF 16949:2016

ISO 9001:2015

Environmental Management System Certificate

Packaging and Transportation

● Prepare appropriate packaging materials, such as anti-static foam, pearl cotton, carton, desiccant, packing belt, sealing glue, etc;

● Use sealant to seal the cardboard box tightly, ensuring that the sealant is firmly attached without any gaps. Stick sealant at the seams of the cardboard box to increase its sealing and strength.

● If the order quantity is not very large, we can send them to you through express delivery such as TNT, DHL, UPS, or EMS.

● If the order quantity is large, we would recommend that you use air or sea freight through your designated freight forwarder. Our long-term cooperative agents can also provide.

we are here for you

Frequently Asked Questions

Hot Tags: 36v 18ah ebike battery case, China 36v 18ah ebike battery case manufacturers, suppliers, factory, Triangle Ebike Battery Box, e-bike battery box for prototype, e-bike battery box for demonstration, e-bike battery box for quality control, e-bike battery box for research and development, Electric Scooter Battery Box

Send Inquiry